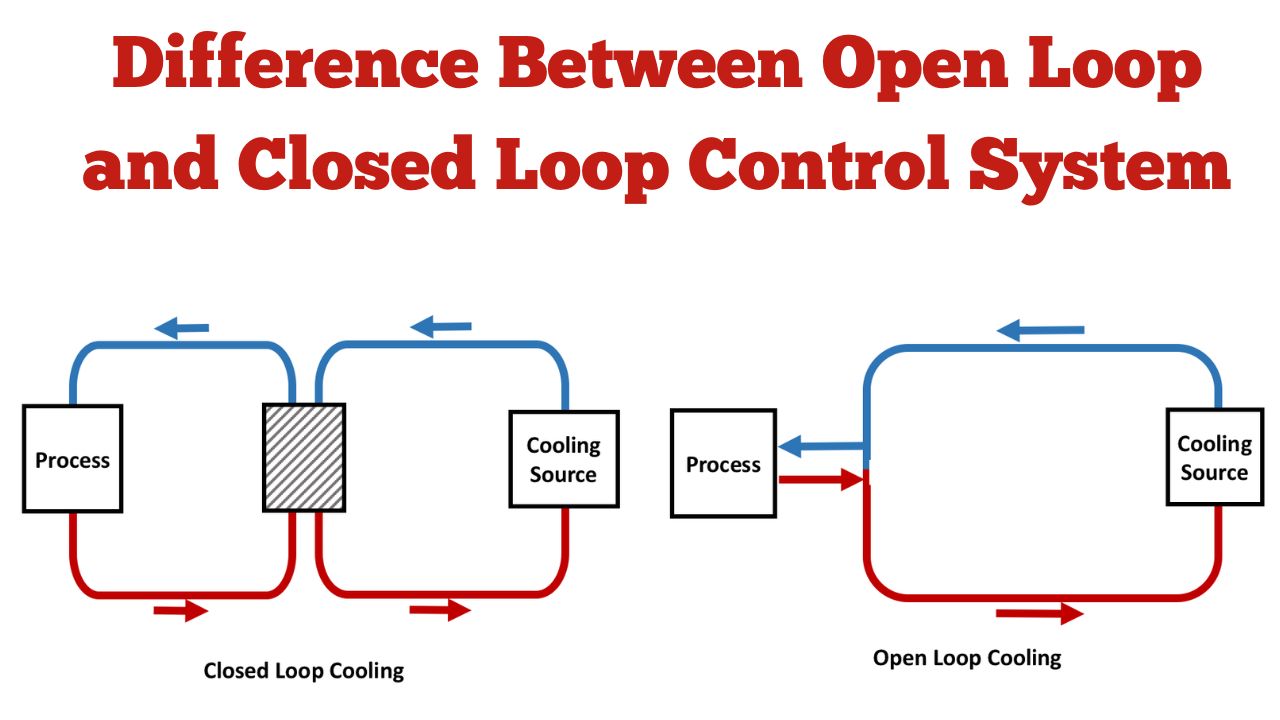

An open-loop control system works without feedback, like a fan running at a fixed speed. In contrast, a closed-loop system adjusts automatically using feedback, like an air conditioner maintaining room temperature. Closed loops are smarter and more efficient.

Ever wondered why some devices work perfectly without you adjusting them? That’s the magic of closed-loop systems! However, how about those that seem not to measure up to or respond to changes? Let’s google some information on one of the most subtle but interesting distinctions between open and closed-loop control systems.

Please continue as we demystify the factors that define open and closed-loop control systems. From humble demonstrations to practical applications, the lessons of these systems concern how these systems constitute general drives of technology in our surroundings.

Open Loop Control System: How It Works

An open-loop control system operates without feedback. It works based on preset conditions. Once started, it doesn’t adjust its operation, even if conditions change.

This system is simple and cost-effective. It’s easy to design and implement. However, it lacks accuracy. Variations in conditions can affect its performance.

Examples include basic household devices. A toaster heats bread for a set time. It doesn’t adjust to the bread’s thickness or starting temperature. Fans with fixed speeds are also open-loop systems.

While effective for simple tasks, it struggles with complex or variable operations. If precision is needed, this system might not be ideal.

Closed Loop Control System: How It Works

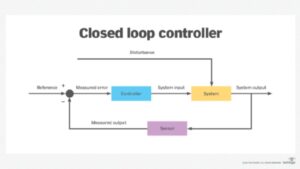

Closed-loop control systems rely on feedback. They monitor output and compare it with a desired value. If there’s a difference, adjustments are made automatically.

These systems are accurate and reliable. They ensure consistent performance, even in changing conditions. However, they are more complex and costly to build.

An example is an air conditioner. It adjusts cooling based on room temperature. Automatic washing machines also use this principle. They sense load and water level to optimize operation.

This system is widely used in modern technology. From industrial machines to home appliances, its precision is crucial.

Key Differences Between Open and Closed Loop Systems

The fundamental distinction between open loop and closed loop control system is that of feedback. It is important to note that open loop systems don’t employ feedback while closed loop systems do.

Table: A field that will be fairly easy to compare is Open-Loop and Closed-Loop Control Systems.

| Aspect | Open-Loop Control System | Closed-Loop Control System |

| Feedback | Does not use feedback. | Uses feedback to monitor and adjust performance. |

| Complexity | Simpler and easier to design. | More complex and requires advanced components. |

| Cost | Cheaper to build and maintain. | Higher cost due to additional components and features. |

| Adaptability | Cannot adapt to changes in conditions. | Automatically adjusts to changes for better accuracy. |

| Precision | Less accurate and reliable. | Highly precise and consistent in performance. |

| Example | A fan running at a fixed speed. | A fan adjusting speed based on room airflow. |

Efficiency Comparison

Open-loop systems are less efficient. They waste resources if conditions vary. For instance, a fixed-timer irrigation system may overwater or underwater plants.

Closed-loop systems are more efficient. They adjust automatically, saving resources. A sensor-based irrigation system waters only when soil moisture drops.

Efficiency often justifies the higher cost of closed-loop systems. In industries, this efficiency reduces wastage and increases output quality.

Applications of Open-Loop Systems

Open-loop systems are suitable for simple, predictable tasks. They are used in devices where feedback isn’t necessary.

Examples include electric kettles, basic traffic lights, and manual dryers. These systems operate reliably when external conditions remain constant.

They are common in cost-sensitive applications. Their simplicity makes them easier to maintain. However, they lack flexibility and adaptability.

Applications of Closed-Loop Systems

Closed-loop systems are ideal for complex tasks. They adapt to changes, ensuring consistent results.

Examples include elevators, thermostats, and autopilot systems. In industries, they control robotic arms and assembly lines.

These systems are essential in modern technology. They improve safety, reliability, and user experience. While costlier, their benefits often outweigh the expense.

Advantages of Open-Loop Control Systems

- Simplicity: Easy to design and use.

- Low Cost: Requires fewer components.

- Quick Operation: No delay for feedback processing.

However, these systems may not suit tasks requiring accuracy or adaptability.

Advantages of Closed-Loop Control Systems

- Precision: Feedback ensures accurate performance.

- Adaptability: Adjusts to changes in conditions.

- Efficiency: Optimizes resource use.

Despite being complex and expensive, these systems are indispensable for advanced tasks.

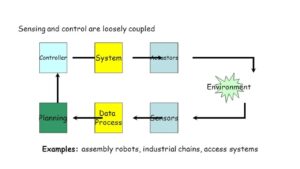

Open-Loop vs. Closed-Loop in Modern Technology

The difference between open loop and closed loop control system is crucial in today’s technology. Open-loop systems remain relevant in simple devices. Closed-loop systems dominate advanced applications.

Smart devices rely heavily on closed-loop systems. For example, smart thermostats adjust heating or cooling based on room occupancy. Fitness trackers monitor heart rate and adjust workout recommendations.

In contrast, open-loop systems still power basic gadgets. They fulfill tasks where feedback isn’t critical, such as traditional lamps or mechanical timers.

Choosing Between Open-Loop and Closed-Loop Systems

The choice depends on the application. Open-loop systems are best for simple, predictable tasks. Closed-loop systems excel in dynamic environments.

Cost is another factor. Open-loop systems are more affordable. Closed-loop systems require higher investment but offer better results.

Understanding the difference between open loop and closed loop control system helps in making informed decisions. It ensures the right system is chosen for the job.

Future Trends in Control Systems

Such systems are dynamic as closed-loop systems are developing with enhanced technology. AI and ML increase their flexibility in them.

Open-loop systems are now rarely seen in high technology applications. However, their simplicity still holds value in basic devices.

With IoT (Internet of Things), closed-loop systems are getting smarter. They connect with other devices, improving efficiency and functionality.

As technology advances, the gap between these systems widens. Closed-loop systems are expected to dominate future applications.

Conclusion

It is imperative not only to know open loop and closed loop control systems, but also comprehend how modern technology works. Open-loop systems operate a pulse and do not require feedback making them less complex but rigid. These include toaster or simple fans. In contrast, closed-loop systems feedback for controlling the degree of performance with a more accurate and effective outcome. Consider such devices as air conditioners or washing machines that operate based on the change that occurs within the device.

This comparison of the open loop and closed loop control system explains their distinct advantages. A major advantage of OLSs is that they are cheaper than CLSs, and their suitability for simple tasks is mentioned earlier. The decision as to which system to use in a particular task, depends on how complicated or challenging that particular task is. Using the concepts explained above you will be able to have a better understanding of the technology that surrounds our daily lives.

FAQs

What is the difference between open loop and closed loop systems?

Open-loop systems work without feedback and don’t adjust to changes. Closed-loop systems use feedback to monitor and correct their performance for better accuracy.

What is the difference between open loop and closed loop converter?

Open-loop converters lack feedback and have fixed settings. Closed-loop converters use feedback to adjust voltage or current for stable output.

What is the difference between open system and closed system?

Open systems exchange energy or matter with the environment. Closed systems do not exchange matter but can exchange energy.

What is the difference of closed loop control system?

Closed-loop control systems use feedback to monitor output and make adjustments automatically for precision and efficiency.

What is an example of open loop control?

A toaster is an example of open-loop control; it heats for a set time without feedback.

Also Read This : How To Keep Stainless Steel Looking Like New