A circuit breaker is a device that stops the flow of electricity to prevent too much current from flowing due to a short circuit or overload. Its main job is to stop the current when there is a problem. A vacuum circuit breaker uses a vacuum to extinguish the arc. Vacuum interrupter technology first appeared in 1960. This article explains what a vacuum circuit breaker is, how it works, its benefits, drawbacks, and uses.

What is a Vacuum Circuit Breaker?

A vacuum circuit breaker uses a vacuum to extinguish arcs during circuit interruptions. The fixed and movable contacts are placed inside a vacuum interrupter, which is a sealed chamber. When the contacts separate in the vacuum, the arc quickly extinguishes.

The process of interrupting the current happens inside the vacuum interrupter. This chamber has a steel arc chamber positioned between ceramic insulators arranged symmetrically. The material of the current-carrying contacts, such as copper-chromium (Cu/Cr), plays a crucial role in the breaker’s performance. Vacuum circuit breakers are commonly used in medium voltage applications, typically ranging from 11 kV to 33 kV.

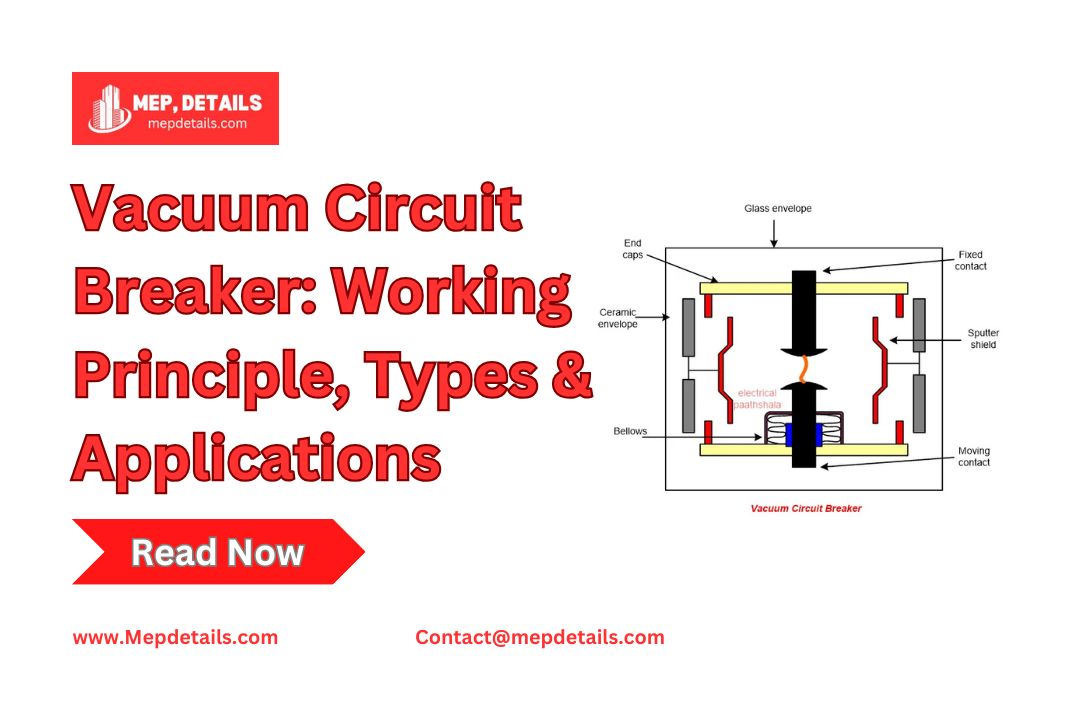

Vacuum Circuit Breaker Construction

Building a vacuum circuit breaker is simpler compared to other types of circuit breakers. Its design consists of three main parts: fixed contacts, moving contacts, and an arc shield inside the arc-interrupting chamber. The outer shell of the breaker is made of glass, which allows easy inspection after use. If the glass changes from its shiny, silvery appearance to a milky color, it indicates that the breaker is losing its vacuum.

The arc shield holds both the fixed and moving contacts. When sealing, the pressure inside the vacuum interrupter stays around 10⁻⁶ torr. The moving contacts travel a distance of 5 to 10 mm, depending on the operating voltage. Stainless steel metallic bellows are used to move the contacts. The design of these bellows is crucial because the breaker’s lifespan relies on their ability to perform repeated operations effectively.

How a Vacuum Circuit Breaker Works

A vacuum circuit breaker works by interrupting the flow of electricity when its contacts open in a vacuum. When the contacts separate, an arc forms due to the ionization of metal vapor between them. This arc gets extinguished quickly because the electrons, ions, and metal vapors produced during the process condense on the contact surfaces. This allows the vacuum to regain its insulating strength quickly.

In a vacuum, if the current to be interrupted is very small, the arc splits into many smaller arcs that spread across the contact surface. These arcs oppose each other and are easy to interrupt. This type of arc is called a diffused arc. When the current is higher, the arc becomes focused in a small area, which can cause the contact surface to vaporize rapidly. If the arc stays in a diffused state, it can be interrupted easily. However, if the arc shifts away from the contact surface, it may reignite.

The materials and shape of the contacts, along with the way metal vapors are handled, play a key role in extinguishing the arc effectively. The arc’s path is kept moving to prevent any one spot from overheating.

After the arc is extinguished, the vacuum circuit breaker quickly regains its insulating strength. This fast recovery makes it suitable for switching capacitors without causing re-strikes. Small currents are interrupted before reaching zero, which may result in varying levels of current chopping, depending on the contact material.

Types of Vacuum Circuit Breakers

Here is a brief explanation of the different types of vacuum circuit breakers:

Outdoor Vacuum Circuit Breaker

Used in outdoor locations where the equipment faces weather conditions. It includes a sealed tank with vacuum interrupters for insulation and to extinguish arcs.

Indoor Vacuum Circuit Breaker

Designed for indoor use in protected environments. It has a similar design to the outdoor version but does not include a heavy-duty enclosure.

SF6 Vacuum Circuit Breaker

Uses SF6 gas for insulation and arc quenching within the interrupter chamber. It has a more compact design compared to air blast breakers.

Oil Vacuum Circuit Breaker

Contains an insulating oil medium along with vacuum interrupters inside the tank. This older design is less common now due to environmental issues related to oil use.

Axial Magnetic Field Vacuum Breaker

Uses vacuum interrupters with an axial magnetic field to extinguish arcs quickly. It is suitable for medium voltage applications up to 72.5 kV.

Phase Segregated Vacuum Breaker

Each phase has its own vacuum interrupter and contact system. This design enhances reliability compared to shared interrupters.

Hybrid Vacuum Circuit Breaker

Combines a vacuum interrupter with SF6 gas or an air blast system for insulation and quenching. It offers better performance than designs using only vacuum or SF6.

Applications of Vacuum Circuit Breakers

Vacuum circuit breakers serve various purposes:

- Their narrow gap and excellent recovery make them ideal as high-speed switches in many industrial settings.

- They work best when handling high voltage and low current, outperforming other types of circuit breakers in these conditions.

- They suit systems with voltages from 11 to 33 kV due to their minimal maintenance needs.

Pros and Cons of Vacuum Circuit Breakers

Here are some key benefits and limitations:

Pros

- Vacuum circuit breakers provide better arc extinction compared to traditional breakers.

- They have strong insulating properties.

- The vacuum acts as a superior dielectric medium compared to other materials used in breakers.

- They last longer and need very little maintenance.

- These breakers are efficient, compact, and cost-effective.

- They don’t need oil or gas refills.

- Their design is compact and self-contained.

Cons

- Manufacturing vacuum circuit breakers requires advanced technology.

- Extra surge suppressors are necessary to interrupt certain low magnetizing currents.

- If the vacuum gets damaged during transit or fails, the interrupter stops working and cannot be repaired on-site.

Conclusion

The vacuum circuit breakers are highly reliable, efficient, and compact, and their applications are for medium voltage. Here, the vacuum technology is utilized to quickly extinguish the arcs and regain the strength of insulation. They require less maintenance and are quite excellent in performance; therefore, they are utilized in various industries. Users can understand their construction, working principles, types, and applications to appreciate their value in modern electrical systems.

FAQs

What is a vacuum circuit breaker used for?

A vacuum circuit breaker uses a vacuum to quench arcs when contacts separate.

How does a vacuum circuit breaker work?

A vacuum circuit breaker works by separating contacts inside a vacuum chamber. This quickly extinguishes the arc and interrupts the current flow.

Why use a vacuum circuit breaker?

Vacuum circuit breakers offer high insulating strength, better arc quenching, longer life, and reliability, making them a good investment.

What are the benefits of a vacuum breaker?

A vacuum breaker equalizes pressure, prevents damage or implosions, and stops siphons and backflow contamination.

Read More – Air Circuit Breaker (ACB) and Its Working Principle