An AC motor is an electric machine that turns alternating current into mechanical movement. AC motors are used in many areas, from large industrial machines to small household devices. In this article, we will briefly talk about how an AC motor works and its key features.

What is an AC Motor?

An AC motor changes alternating current into mechanical power. It has two main parts: the stator and the rotor. The stator stays still, while the rotor moves. AC motors can be either single-phase or three-phase. Nikola Tesla invented the first AC induction motor in 1887.

Components of an AC Motor

An AC motor runs using alternating current. It has two main parts: the stationary stator and the rotating rotor. Let’s take a closer look at the different components of an AC motor.

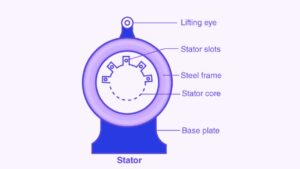

Stator

The stator is the part that stays still and creates a rotating magnetic field to interact with the rotor.

Stator Core

The stator core is made of thin metal sheets called laminations, which help reduce energy loss.

Stator Windings

The stator windings are groups of insulated wires arranged in a hollow cylinder shape. These windings are connected to a power source when the motor is in use. When current flows through the coils, they turn into electromagnets along with the steel core.

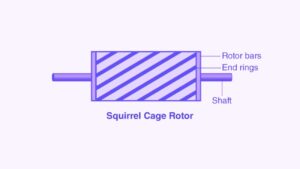

Rotor

The rotor is the rotating part of the motor, attached to a shaft. The most common type is the squirrel cage rotor, which has a cylindrical shape and is made of thin steel laminations. Instead of using wire coils, it has conductor bars placed in the slots around the cylinder. These bars are connected to end rings, both mechanically and electrically.

Motor Shaft

The rotor is attached to a steel shaft, forming the rotor assembly. The shaft sticks out of the motor casing and connects to external systems to transfer rotational power.

Bearings

Bearings support the motor shaft and reduce friction between the shaft and the casing. This helps the motor work more efficiently.

Enclosure

The enclosure covers and protects the motor’s internal parts from water and other elements. It includes a frame and two end brackets.

Benefits of AC motors

As a manufacturer of electric motors, we know how useful our AC gear motors can be for industries around the world. Here are some key benefits to consider:

Durable

AC motors last longer because, unlike most DC motors, they don’t have brushes. Brushes wear out quickly and need regular maintenance. Since AC motors don’t have this issue, they often have a longer lifespan, making them a popular choice for those seeking a durable option.

Low Power at Start-Up

AC motors need less power to start, which helps them distribute power evenly and maintain a steady level of energy during operation. This lowers the risk of burnout, which can occur when a motor overworks at the start.

Controlled Acceleration

AC motors offer smooth and controlled acceleration, which is important for many demanding tasks. This steady movement also reduces wear and tear since speeds don’t change suddenly. For applications like caravan movers, controlled acceleration ensures stable and consistent speed, which is essential for proper performance.

High Speed

AC motors can handle and deliver high speeds, making them suitable for various demanding industrial applications.

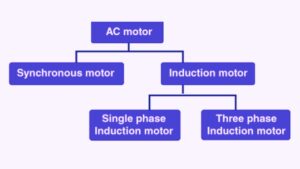

Types of AC Motors

AC motors are classified based on how they operate. Let’s look at the different types of AC motors.

Synchronous Motor

A synchronous motor runs at a constant speed called synchronous speed. This speed is the same as the speed at which it generates electromotive force. The motor has an electromagnet that locks with the rotating magnetic field and rotates at the same speed. This is why it is called a synchronous motor, and its speed remains constant.

How a Synchronous Motor Works

A synchronous motor needs two electrical inputs:

- The stator gets a 3-phase AC supply.

- The rotor gets a DC supply.

The stator’s 3-phase AC supply creates a rotating magnetic field. The rotor’s DC supply creates a constant magnetic field. Sometimes the rotor and stator poles match (N-N or S-S), which causes repulsion. The next moment, they attract (N-S). This attraction and repulsion prevent the motor from rotating.

To solve this, the rotor first gets mechanical input to move it in the same direction as the magnetic field. After a while, the rotor locks with the magnetic field and rotates together with it, making the motor work at a synchronous speed.

Induction Motor

- Squirrel Cage Motor

- Slip Ring Motor

How an Induction Motor Works

In an induction motor, the stator gets an AC supply, which creates a rotating magnetic field (RMF). According to Faraday’s Law of Electromagnetic Induction, the difference in speed between the stator’s RMF and the rotor causes an induced electromotive force (emf) in the rotor. This emf creates a current in the rotor conductors, which short-circuit.

This rotor current produces its own magnetic field. The rotor tries to reduce the difference in speed between itself and the stator’s rotating magnetic field by turning in the same direction. This is how an induction motor works.

Applications of AC Motors

AC motors are popular for several reasons:

- Long-lasting AC motors can last for years because they have only a few moving parts. Their durability makes them a good choice for field work like farming equipment and for commercial uses such as vending machines.

- Efficient AC motors perform well in many tasks without overheating or breaking down, thanks to their speed-to-torque balance. This makes them a great option for high-demand tasks like pumps and packaging machines.

- Quiet AC motors produce less noise, making them perfect for places like stores, hospitals, and restaurants.

- Widely Available AC motors come in various sizes and power levels, making them suitable for many different uses.

Conclusion

An AC motor has two main parts: the rotor (which rotates) and the stator (which stays still). The stator’s main job is to transfer the magnetic rotary field to the rotor. The steel shafts, which extend outside the motor, attach the rotor and connect to external systems for transmitting power. By changing the motor’s slip and the frequency of the AC signal, you can control the motor’s speed. AC motors are powerful for their weight, cost-effective, and require little maintenance.

FAQs

When was the AC motor invented?

Nikola Tesla invented the first AC induction motor in 1887.

What are the advantages of an AC motor over a DC motor?

AC motors produce higher torque, and using a controller, you can adjust power and speed without sparking.

What is the working principle of an AC motor?

AC motors generate rotational force through magnetic flux and induced current created by the stator and rotor.

What is a synchronous speed?

Synchronous speed is the constant speed at which the motor generates electromotive force.

How can you differentiate an AC motor from a DC motor?

An AC motor has no commutator and only brushes, while a DC motor has both commutator and brushes.

What are the 3 types of motor?

DC motors, AC motors (synchronous, asynchronous, and induction), and special-purpose motors.

How many AC motors?

AC motors are classified into synchronous and induction motors.

What are the 4 types of single-phase AC motors?

Read More – Moore’s Law: A Beginner’s Guide to the Future of Technology