Air circuit breaker is an electrical device that controls and protects circuits. It can break a circuit manually or remotely during normal conditions and shuts it off in case of faults like short circuits or overcurrents. Circuit breakers often work alongside devices like relays, switches, and fuses to ensure safety. They are widely used in power systems and industries to protect and control components such as transformers, motors, and generators. Among various types of circuit breakers, the air circuit breaker (ACB) is a common choice. This article explains the air circuit breaker and its working principle.

What is an Air Circuit Breaker?

An air circuit breaker (ACB) is an electrical device that protects circuits from overcurrent and short circuits. It works with electric currents ranging from 800 amps to 10,000 amps and is mainly used in low-voltage systems under 450 volts. You can often find air circuit breakers in distribution panels within this voltage range.

This device uses air at a specific atmospheric pressure to extinguish arcs during circuit operation. Modern air circuit breakers are durable, efficient, and easy to install and maintain. They have completely replaced oil circuit breakers because they avoid the risk of oil fires.

Key features of air circuit breakers include:

- Using air at atmospheric pressure to quench arcs.

- No risk of oil fire compared to oil circuit breakers.

- Supporting current ratings of up to 10,000 amps.

- Customizable trip thresholds and delays.

- Electronic and microprocessor-based controls.

- Common use in large industrial plants for primary power distribution.

- This post will explain how air circuit breakers work in more detail.

Components of ACB

Main and Auxiliary Contacts

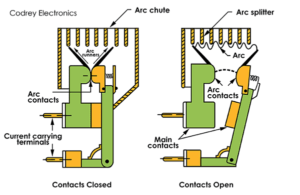

An ACB has two types of contacts. The main contacts, made of copper, carry the current. The auxiliary or arcing contacts, made from copper alloy, protect the main contacts by handling the arcing.

Arc Chute

The arc chute is a chamber around the contacts. It uses a heat-resistant material to cool and extinguish the arc. The inner walls guide the arc into a compact area, making it easier to quench.

Trip Units

The trip unit identifies issues and opens the contacts. It includes safety relays and sensors that monitor current and voltage levels in the circuit.

Closing and Opening Mechanisms

Springs, solenoids, and mechanical links control the ACB’s closing and opening actions. These mechanisms ensure smooth and reliable switching.

Construction of an Air Circuit Breaker

An air circuit breaker has many internal and external parts.

The external parts include the ON/OFF button, a main contact position indicator, an energy storage mechanism indicator, LED indicators, an RST button, a controller, nameplates with ratings, energy storage handles, displays, rocker repositories, shake buttons, and fault trip reset buttons.

The internal parts include a steel structure, a current transformer for the trip unit, a pole group insulating box, horizontal terminals, an arcing chamber, a protective trip unit, a terminal box, closing springs, controls for opening and closing the breaker, and movable and stationary plates for both the arcing and main contacts.

Air Circuit Breaker Working Principle

The air circuit breaker works differently from other types of circuit breakers. A circuit breaker’s main job is to stop arcing when the gap between the contacts can resist the system’s recovery voltage.

The air circuit breaker performs this task in its own unique way. During arc interruption, it creates an arc voltage instead of relying on the voltage supply. This arc voltage is the minimum voltage needed to keep the arc going. To stop the arc, the breaker has three ways to increase the arc voltage:

- Cooling the Arc Plasma: Lowering the temperature and particle speed in the arc plasma increases the voltage needed to keep the arc going.

- Breaking the Arc into Multiple Parts: Splitting the arc into several smaller arcs increases the voltage.

- Expanding the Arc Path: Increasing the length of the arc path raises the resistance and, in turn, the voltage required to maintain the arc.

The operating voltage for an air circuit breaker is up to 1KV. It has two contact sets: a primary pair made of copper for carrying the current and a secondary pair made of carbon. When the breaker opens, the primary contact separates first.

While the primary contact opens, the arc contact stays connected for a moment. Arcing starts when the arc contacts separate. Air circuit breakers are not commonly used for medium voltage systems today.

How Air Circuit Breakers Work

Air circuit breakers interrupt currents using exposed contacts in free air and a unique arc-quenching method. Commonly used for low-voltage systems, they are replacing high-voltage oil breakers.

They have two contact pairs: copper primary contacts and carbon arcing contacts. During opening, the primary contacts separate first, while the arcing contacts maintain a low-resistance path. Arcing begins when the arcing contacts separate.

Thermal and electromagnetic effects push the arc upward into an arc chute, which cools and stretches the arc before extinguishing it at zero current. The chute, made of fireproof and insulating materials, has barriers with conductive elements to maintain continuity.

Types of Air Break Circuit Breakers

Air circuit breakers are of four types and are used for medium voltage applications in homes:

Plain Break Type ACB

This is the simplest air circuit breaker. Its main contacts look like two horns, and the arc moves from one end to the other. It uses an arc chute, made of refractory material, with internal walls divided by iron plates (arc splitters). These split the arc into smaller arcs, raising arc voltage above system voltage. It is used for low-voltage applications.

Magnetic Blowout Air Break Circuit Breaker

This breaker handles voltages up to 11KV. Blowout coils create a magnetic field that directs the arc into the arc chute for cooling and extension. The arc is controlled magnetically, ensuring better arc extinction. These are common for 11KV systems.

Air Chute Air Break Circuit Breaker

This type has two contacts: main (copper or silver-plated for low resistance) and arcing (made of heat-resistant copper alloy). The arcing contacts protect the main ones and can be easily replaced. The breaker opens or closes the main contacts after or before the arcing contacts.

Air Blast Circuit Breaker

These breakers handle voltages from 245KV to 420KV or higher. They operate quickly, with efficient arc quenching and reduced heat transfer, extending the life of contacts. They also require less maintenance and improve system stability.

Benefits of Air Circuit Breakers

Air circuit breakers (ACBs) provide several benefits:

- Safety: Using air to stop the current removes the fire risks that come with oil-filled breakers.

- Fast Operation: ACBs quickly interrupt the current, reducing damage during faults.

- Low Maintenance: Their simple design needs less maintenance than other types.

- Environmentally Friendly: Air doesn’t cause the environmental issues linked to oil disposal.

- Versatility: ACBs are available in different sizes, suitable for low to medium-voltage applications.

Maintenance of Air Circuit Breaker (ACB)

Air Circuit Breakers (ACBs) protect systems requiring low voltage (up to 600V AC) in UPS, generators, and power distribution boards, with capacities ranging from 400A to 6300A or more. Poor maintenance, grease buildup, dust, corrosion, or frozen parts can cause 20% of power distribution failures. Regular maintenance ensures reliable operation and a longer lifespan.

Key Maintenance Steps:

- Turn off the ACB and disconnect it from both sides using the electrical isolator.

- Test the breaker annually in no-isolation situations, especially in restricted areas.

- Operate the breaker electrically and mechanically to remove external layers on sliding edges, improving its consistency.

Conclusion

That’s everything about Air Circuit Breakers (ACBs), how they work, and their applications. We hope this has helped you understand the concept better. If you have any questions or need help with electrical and electronic projects, share your thoughts in the comments below.

FAQs

What is the ACB breaker working principle?

Air Circuit Breakers (ACBs) use pressurized air to prevent arcs when contacts separate. This keeps the current stable and safe, making ACBs a safer alternative to oil circuit breakers.

What is the working principle of AC circuit breaker?

An AC circuit breaker contains a metal alloy that heats up and breaks when overloaded, preventing short circuits. The melted alloy interrupts the power supply to the circuit.

What is the air break circuit breaker?

An Air Circuit Breaker (ACB) protects circuits from overcurrent and short circuits, typically for currents between 800 Amps and 10K Amps. It is commonly used in low-voltage systems below 450V, like Distribution Panels.

What is the working principle of circuit breaker?

In a circuit breaker, current-carrying contacts, or electrodes, touch each other under pressure from a spring to allow current flow. When the circuit is closed, these contacts engage to carry the current.

Read More – Single Phase Transformers: A Vital Component in Electrical Circuits