An Automatic Slip Regulator (ASR) Starter helps start and control electric motors, especially large ones used in industries. The ASR Starter makes starting up smooth and controlled, reducing stress on both the motor and the connected machinery. In this article, we’ll cover the components, operation, features, and applications of the Automatic Slip Regulator Starter.

What is an Automatic Slip Regulator Starter (ASR Starter)?

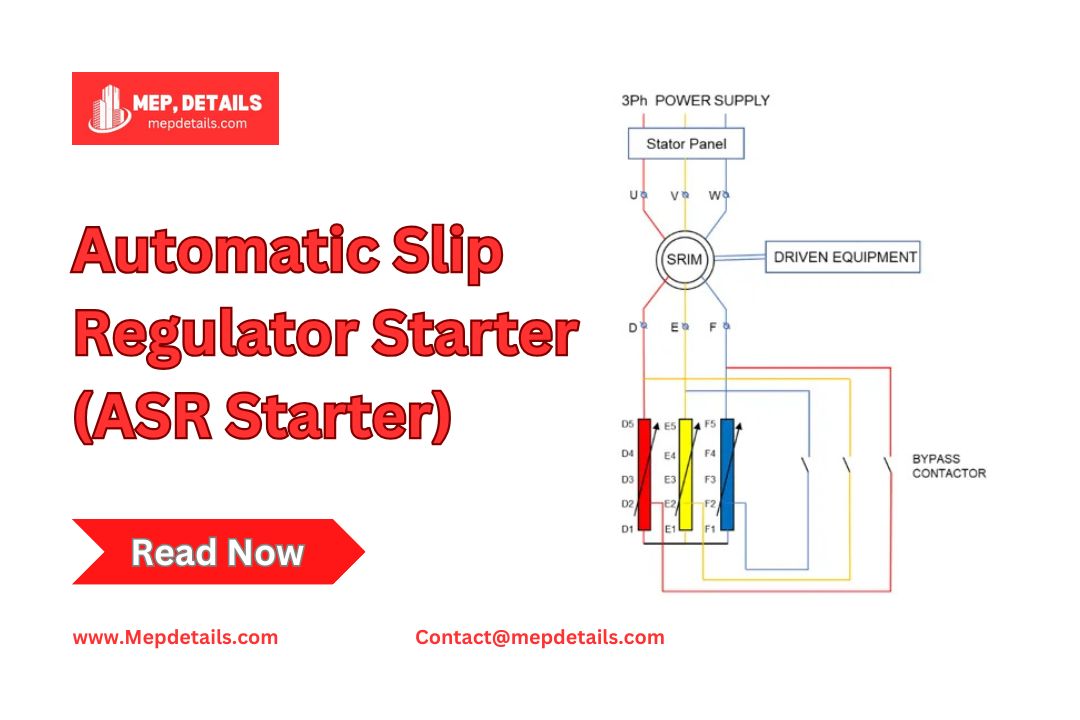

An Automatic Slip Regulator Starter (ASR Starter) is a special device that controls the start and operation of slip ring induction motors. These motors, often used in heavy industrial applications, need controlled starts to reduce mechanical strain and electrical disturbances. The ASR Starter helps by managing the slip, which is the difference between the motor’s synchronous speed and actual speed, allowing for smooth acceleration and deceleration.

Components of an Automatic Slip Regulator Starter

- Slip Ring Induction Motors: This motor needs slip adjustment for proper function.

- Rotor Resistors: External resistors connect to the rotor circuit to adjust slip.

- Contactor Relays: These switches connect or disconnect rotor resistors as needed.

- Control Units: Use a microcontroller or PLC to automate the starter’s operation.

- Current Sensors: Measure the motor’s current to determine slip.

- Voltage Sensors: Keep track of the voltage at the motor terminals.

- Speed Sensors: Measure motor speed to calculate slip.

- Thyristors with SCRs (Silicon Controlled Rectifiers): Use these electronic devices to control resistance levels.

- Power Supply Units: Supply power to the control circuit and sensors.

- Cooling Systems: Manage heat from resistors and electronic parts.

- Display Panel: Provides an interface for monitoring and setup.

- Protective Devices: Use fuses, circuit breakers, and overload protection to keep the system safe.

How Does an Automatic Slip Regulator Starter Work?

- Starting the Motor: The motor begins with high rotor resistance to keep the starting current low.

- Measuring Current: Current sensors track the rotor’s current as the motor starts.

- Calculating Slip: Speed sensors provide data on rotor speed. Slip is calculated by finding the difference between the synchronous and rotor speeds.

- Adjusting Resistance: The control unit adjusts rotor resistance based on slip and current measurements, using contactors or thyristors.

- Reducing Resistance Gradually: As the motor accelerates, resistance steadily decreases, allowing smoother acceleration and less slip.

- Reaching Steady Operation: When the motor nears synchronous speed, the rotor resistance lowers, letting the motor run at maximum efficiency.

- Adjusting for Load Changes: If the load changes, the control unit adjusts rotor resistance to keep the right slip and prevent stalling or overloading.

Slip Calculation of an ASR Starter

The slip regulator has a resistance that changes with frequency. When the motor starts at zero speed, the rotor frequency matches the supply frequency, so the slip regulator resistance is at its highest. When the motor is running, the rotor frequency is low (depending on slip), and the slip regulator resistance is low.

Features of ASR Starter

Smooth Start

The ASR Starter gradually speeds up the motor, lowering the initial surge of current and reducing mechanical shock. This smooth start helps the motor and related systems last longer.

Slip Regulation

The ASR Starter adjusts the resistance in the rotor circuit, controlling slip to produce the best torque and allowing the motor to work efficiently during start-up and under changing loads.

Reduced Electrical Stress

The controlled starting current prevents voltage dips and reduces strain on the electrical network, ensuring smooth operation for other equipment on the same power source.

Enhanced Protection

ASR Starters include protections like:

- Overcurrent protection

- Thermal overload protection

- Phase failure protection

These features protect the motor and starter from damage.

Energy Efficiency

By improving the start-up process and cutting down on losses from high starting currents, the ASR Starter boosts energy efficiency and lowers costs in industrial operations.

Applications of ASR Starter

ASR starters are commonly used in industries that rely on slip ring induction motors, such as:

- Mining: They power heavy-duty conveyors, crushers, and mills.

- Cement industry: They are used for ball mills, crushers, and kiln drives.

- Steel industry: They power rolling mills, crushers, and hoists.

- Power plants and water treatment facilities: They operate pumps, fans, and compressors.

Conclusion

The Automatic Slip Regulator (ASR) Starter plays a crucial role in efficiently starting and controlling slip ring induction motors in various industrial applications. It ensures smooth acceleration, reduces mechanical stress, and lowers electrical disturbances, thereby improving the longevity of motors and connected systems. With its features like slip regulation, energy efficiency, and enhanced protection, the ASR Starter significantly contributes to the performance and safety of industrial operations. Its applications across industries such as mining, cement, and steel demonstrate its versatility and importance in modern machinery.

FAQs

What is an automatic slip regulator?

An automatic slip regulator (ASR) is a device that adjusts the resistance based on the motor’s rotor frequency. It helps provide more torque when the motor load increases.

Which starter is used for a slip ring?

A rotor resistance starter is used for high-rated slip ring induction motors.

What is the principle of a rotor resistance starter?

A rotor resistance starter is used with high-rated slip ring induction motors. It adds external resistance to the rotor circuit, allowing the rotor to produce high torque, especially at low speeds, when the external resistance is higher.

What are the advantages of a resistance starter?

A rotor resistance starter controls the motor’s start-up, reducing electrical and mechanical stress on the motor and related equipment. This improves the reliability and lifespan of the machinery, helping ensure steady and efficient power generation.

Read More – Electrical Power Distribution System: Components & Classification