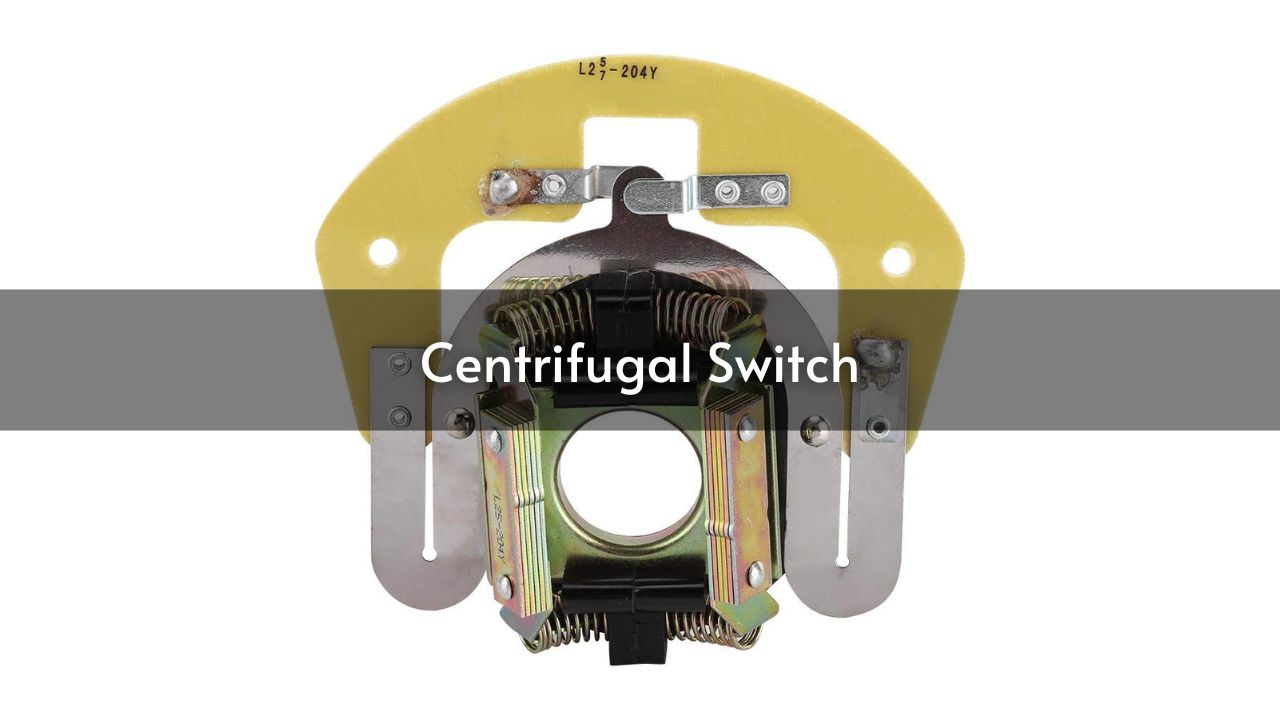

A centrifugal switch is a mechanical device commonly used in single-phase asynchronous motors. When the motor reaches 70-80% of its synchronous speed, the switch disconnects the starting capacitor, allowing the motor to run at its proper torque and current. These switches are important for improving motor efficiency, especially with today’s technology. They help manage power distribution and control motor speed. As the motor accelerates, the centrifugal switch ensures it operates efficiently, meeting energy-saving goals. This makes centrifugal switches an essential part of modern motor control systems, supporting both performance and sustainability.

What Is a Centrifugal Switch in a Motor?

A centrifugal switch plays a key role in helping a motor start up efficiently. It keeps the start capacitor connected to the circuit during the first moments of the motor’s operation, giving the motor the extra power it needs to start. This helps the motor reach the necessary starting torque. By using the centrifugal switch, the motor performs better right from the beginning, improving energy efficiency and extending the motor’s lifespan. The use of the centrifugal switch shows how motor control has advanced to meet the needs of modern industry and technology.

How Does a Centrifugal Switch Work?

Centrifugal switches have evolved into various designs, all working on the basic principle of using rotation to activate the switch in motors. As the motor spins, the switch uses this movement to press on contacts, keeping the start capacitor in the circuit during the motor’s initial operation. Once the motor picks up speed and starts rotating, the centrifugal switch automatically pulls away, disconnecting the start capacitors. This precise timing of mechanical parts ensures the motor starts efficiently and operates reliably throughout its life.

How Does a Centrifugal Switch Work in a Motor?

A centrifugal switch is an important part of many single-phase electric motors. It works using centrifugal force and mechanical movement. When the motor starts, both the rotor and the centrifugal switch are still. As the rotor begins to spin, the centrifugal force acts on weighted parts inside the switch. These parts move, changing the position of the switch.

At first, the switch keeps the starting capacitor connected to the motor’s circuit. This helps the motor get enough torque to start. Once the motor speeds up and reaches about 70-80% of its full speed, the centrifugal switch moves to disconnect the starting capacitor. This helps the motor run more efficiently and reduces strain on the system. The centrifugal switch helps the motor work well both during start-up and while running.

Centrifugal Switch Symbol

A centrifugal switch is a type of switch that can be shown with an electronic symbol. An electronic symbol is a simple picture used in circuit diagrams to represent different electrical devices or functions, like wires, batteries, resistors, and transistors.

A switch is an electrical device that can either connect or disconnect the path in an electrical circuit. It can also change the direction of the electrical current from one conductor to another.

A centrifugal switch works when the shaft rotates. It responds to speed or direction, opening only when the speed increases.

How to Test a Centrifugal Switch

It’s always best to test the centrifugal switch before using it. An ideal centrifugal switch should meet these criteria:

- The process should remain consistent throughout its entire life.

- The design should be simple with as few components as possible to keep production costs low.

- It should have minimal friction.

- The cut-out/cut-in ratio should be easy to adjust without needing major design changes.

- The switch is easy to access since its communication unit is on the outside of the motor frame. This allows you to test, clean, and replace the switch without taking apart the motor assembly.

Applications of a Centrifugal Switch

A centrifugal switch is commonly used in systems that need speed detection to keep the computer safe and working correctly. Here are some common uses of the centrifugal switch:

- Protects against overspeed in motors, generators, and other equipment.

- Used in DC motors, conveyors, escalators, lifts, and similar devices.

- Helps detect under-speed in devices like blowers, fans, and conveyors.

- Prevents material loss in systems where a drop in speed could damage the equipment.

What happens if the centrifugal switch does not open?

If the start switch does not open when needed, the start winding will overheat and burn out, causing the engine to fail to start next time. If the centrifugal start switch doesn’t close, the main winding will overheat, but the main winding itself won’t fail.

Where to Find the Centrifugal Switch in an Electric Motor?

The centrifugal switch is usually placed on the motor shaft, near either the front or rear bearing. This location ensures the switch works properly. As the motor spins, centrifugal force activates the switch, allowing the motor to smoothly shift from start-up mode to normal operation. The switch helps control the starting capacitor, improving the motor’s performance and lifespan.

Which Motors Use a Centrifugal Switch?

Single-phase motors that need high starting torque use centrifugal switches. The Gamak MK21D series of motors use a centrifugal switch along with start and permanent capacitors. In single-phase asynchronous motors, the magnetic field forms due to the phase difference between the main and auxiliary windings. The start capacitor briefly enters the circuit to provide the high torque needed at startup. This is why centrifugal switches are used in these motors.

Centrifugal Switch in Induction Motors

To understand how the centrifugal switch works in induction motors, let’s first look at how these motors are designed. Induction motors have a single stator winding and an auxiliary winding. A single-phase AC current flows through the stator winding.

However, the single stator winding alone cannot create enough rotating field to start the motor. This is why the motor has an auxiliary winding. The auxiliary winding creates a field that is out of phase with the stator field, producing the starting torque needed to begin the motor’s operation. Once the motor starts, the rotor creates a pulsating field that no longer relies on the stator field.

When the motor reaches a certain speed, usually a percentage of the synchronous speed, the circuit powering the auxiliary winding needs to be disconnected. This is where the centrifugal switch comes in. It helps open the circuit and disconnect the auxiliary winding once the motor has started.

Conclusion

The centrifugal switch is important for making electric motors more efficient and effective, ensuring the motor runs free and without unnecessary strain. This device disengages the starting capacitor at the right time so the motor runs free and smooth, without unnecessary strain. This simple device is very important for single-phase motors as it allows these to start and run correctly and reliably. Applications to various industries find it to be a crucial part in the modern motor control systems, and hence an indispensable component in energy-saving and motor longevity.

FAQs

What is a centrifugal switch?

A centrifugal switch is an electrical part that monitors the motor’s speed. It automatically turns off the power when the motor reaches a certain speed to protect it from damage.

What is a centrifugal speed switch used for?

Centrifugal speed switches are commonly used in single-phase, split-phase induction motors. They disconnect the motor’s starting winding when the motor reaches its normal operating speed.

What is the function of centrifugal?

Centrifugal pumps move fluids by turning rotational energy into the fluid’s flow. This energy usually comes from an engine or electric motor. They are a type of dynamic machinery that absorbs work and operates in a circular motion.

Is a centrifugal switch normally open or closed?

A centrifugal switch is normally closed when the motor starts.

Read More – AC Motors: Types, Applications, and Benefits