Imagine you are traveling on a train and the motorman suddenly uses the brakes. Do you know how these brakes work to stop the train? The answer is Eddy Current. Let’s learn what eddy currents are and explore their different uses.

What is an Eddy Current?

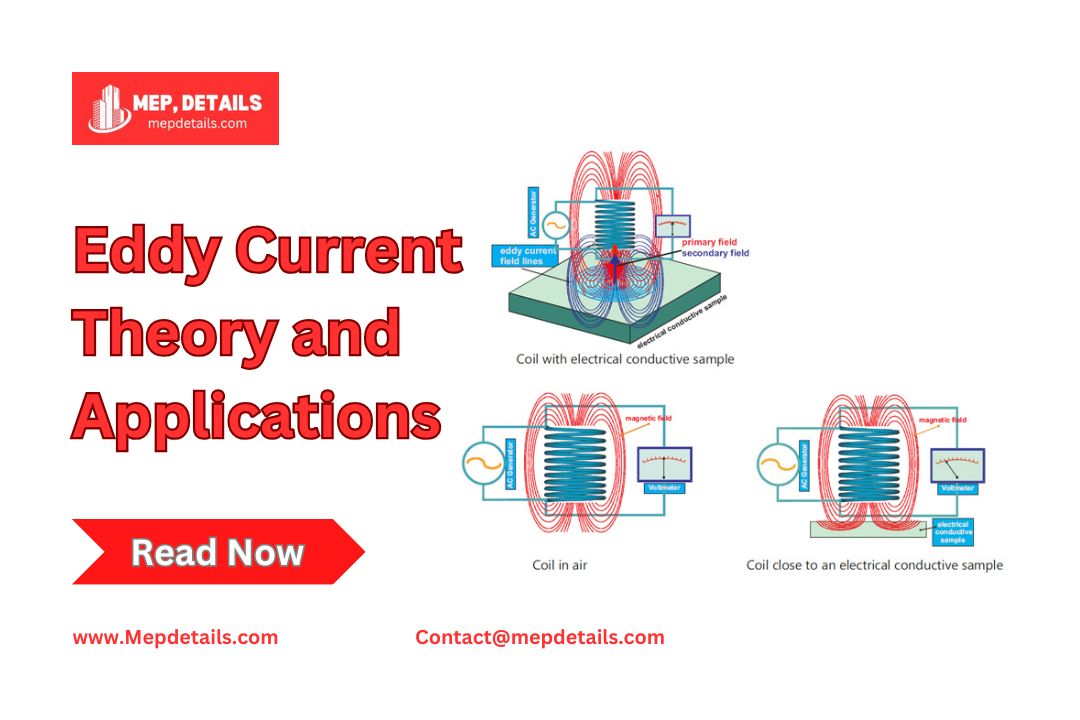

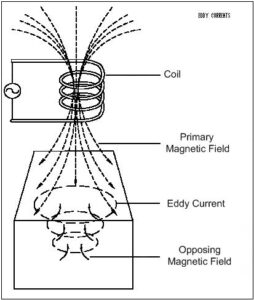

An eddy current is a type of electric current that forms in a conductor when a magnetic field changes. These currents flow in loops that stay on a plane at a right angle to the magnetic field. According to Lenz’s law, the eddy current creates a magnetic field that pushes against the change in the original magnetic field. For this to happen, electrons move in loops in the conductor at a right angle to the magnetic field.

Eddy currents resist changes in motion, which leads to a loss of energy. They convert energy forms, like kinetic energy, into heat, which often isn’t very useful.

Eddy Current Loss in Transformers

The magnetic field inside a transformer core creates an emf, which causes eddy currents to form based on Faraday’s and Lenz’s laws. In the core, the magnetic field B(t), created by the winding current i(t), produces eddy currents, ieddy.

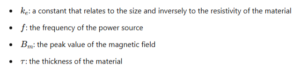

Eddy current loss depends on certain factors:

Eddy current loss increases with higher flux density, frequency, and material thickness, but decreases as material resistivity goes up.

To lower eddy current losses in transformers, manufacturers make the core from thin, stacked plates called laminations. Each plate has insulation, which restricts eddy currents to small areas, shortening their path and lowering losses.

Transformers often use cold rolled grain-oriented (CRGO) steel in the core to boost the material’s resistivity. Eddy currents are also useful for spotting cracks and damage in metals across power, aerospace, and petrochemical industries.

Applications of Eddy Current

Train Brakes

When brakes are applied in trains, the metal wheels pass through a magnetic field. This field generates eddy currents in the wheels. These currents slow down the wheels due to the magnetic interaction with the field. As the train slows down, the braking effect gradually decreases, allowing a smooth stop.

Electromagnetic Damping

Eddy currents help make some devices, like deadbeat galvanometers, settle faster. In normal cases, a galvanometer needle swings before stopping at its position. This delay can make readings slower. To solve this, the coil sits on a non-magnetic metal frame. When the coil moves, eddy currents appear in the frame, stopping the needle almost immediately. Some galvanometers also have a fixed core made of non-magnetic metal. When the coil moves, eddy currents in the core slow down the coil’s movement, helping it stop quickly.

Electric Power Meters

In electric meters, a shiny metal disc spins due to eddy currents. The magnetic field causes these currents, which make the disc rotate. You can see this shiny disc in meters at home.

Induction Furnace

Induction furnaces use eddy currents to create high temperatures. When metal sits in a rapidly changing magnetic field, large eddy currents appear, producing enough heat to melt the metal. This process helps extract metals from ores and make alloys by melting metals at high temperatures.

Speedometers

Vehicles use eddy currents in speedometers to measure speed. A magnet inside the speedometer spins based on the vehicle’s speed. Eddy currents form in a nearby drum, which moves with the rotating magnet. A pointer attached to this drum shows the vehicle’s speed.

Conclusion

Eddy current plays a vital role in many industries, from braking trains to melting metals. They create useful effects like braking and heating by resisting motion and producing heat. Industries like power and aerospace benefit from eddy currents in applications such as testing metals for cracks and damage. Whether in train brakes, electric meters, or speedometers, eddy currents show how the principles of electromagnetism help in practical and innovative ways across different technologies.

FAQs

What are the applications of eddy current sensor?

Eddy current sensors measure the displacement and position of conductive targets. They work for both ferromagnetic and non-ferromagnetic materials.

What are the applications of eddy current testing?

Eddy current testing checks surfaces and tubes for flaws. It is a highly sensitive method that can detect even small cracks or issues on or just below a surface. It works with both ferromagnetic and non-ferromagnetic materials.

What is the eddy current theory?

Eddy currents occur when a conductor is in a changing magnetic field. These are loops of electrical current created in conductors due to this changing field, based on Faraday’s law of induction.

What are eddy currents and its applications?

Eddy currents generate heat. When a metal coil is placed in a high-frequency magnetic field, it heats up enough to melt. This process helps extract metals from ores.

Read More – Efficiency of Transformer