Transformer efficiency is a key factor to consider when choosing a transformer. It shows how well a transformer converts electrical energy with minimal losses. Efficiency is the ratio of output power to input power. In an ideal transformer, efficiency would be 100%, but real transformers have losses that reduce it. Main losses include copper loss in windings, core loss due to hysteresis and eddy currents, stray load losses, and dielectric losses. Good design and material choice can reduce these losses and improve efficiency. In this article, we’ll explore transformer efficiency, its benefits, all-day efficiency, and maximum efficiency conditions.

What is Transformer Efficiency?

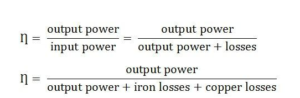

Transformer efficiency tells us how well a transformer converts input power to output power. We calculate it as a percentage by comparing output power (Po) to input power (Pi).

To find efficiency in terms of volt-amperes (VA), we use:

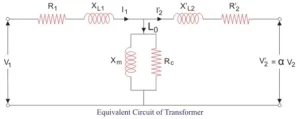

- Input VA = Voltage applied to primary windings × Current in primary windings

- Output VA = Voltage across secondary windings × Current in secondary windings

Terms to Know:

- Cosφ: Power factor of the load

- V2: Voltage at the secondary terminal

- I2: Full load current at the secondary side

- Cosϕ2: Power factor of the load

- Pi: Iron losses, including hysteresis and eddy current losses

- Pc: Copper losses under full load, calculated as I2² × Res

If we consider x as a fraction of the full load, we can calculate efficiency for that fraction. Copper losses change depending on the load fraction.

For energy conservation, the input VA should equal the output VA plus transformer losses. In real situations, transformer efficiency ranges between 95-99% for distribution transformers and can reach up to 99.7% for large power transformers.

Condition for Maximum Efficiency

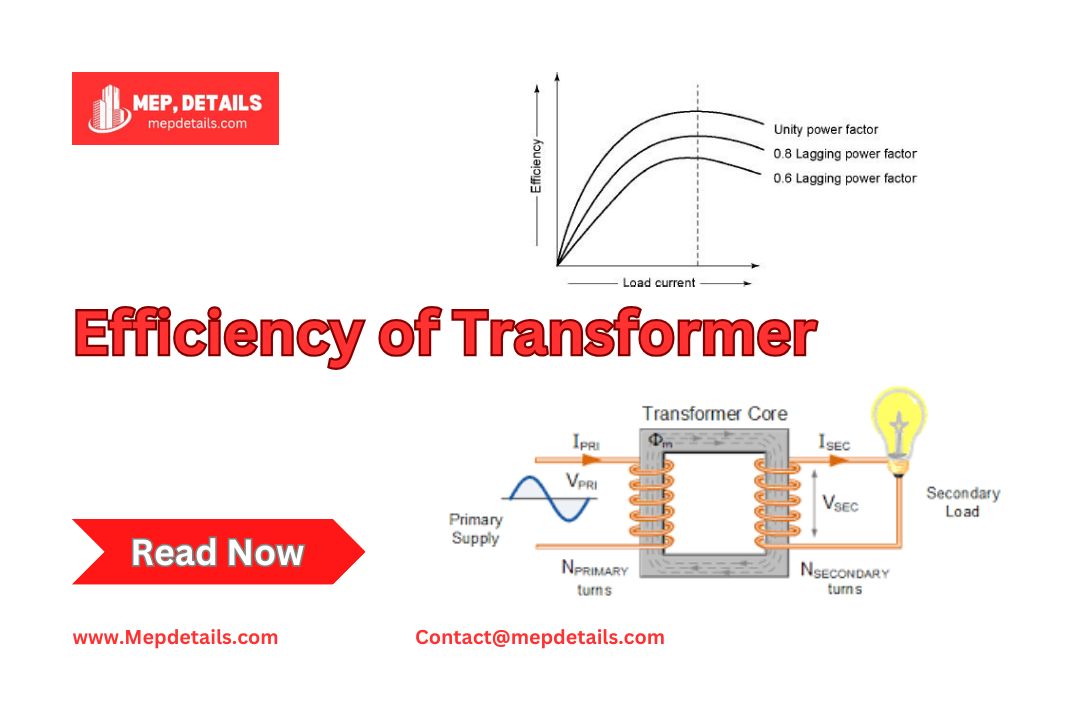

A transformer runs at its highest efficiency when its copper losses equal its iron (or core) losses for a specific load and power factor.

In simple terms:

- Iron loss depends on flux and frequency.

- Copper loss depends on the square of the current.

Iron losses stay the same regardless of the load since they depend on voltage. Copper losses change with the load because they depend on current. When copper losses equal iron losses, the efficiency becomes highest.

Explanation

The efficiency of a transformer, considering load and power factor, follows this relationship:

- The terminal voltage (2) remains mostly constant. So, for a set power factor, transformer efficiency depends on load current (2). In this formula, the numerator stays the same. Efficiency will reach its peak when the denominator, in terms of 2, hits zero.

- The output current (2) where transformer efficiency is at its best happens when copper losses match iron losses.

Given:

- represents the fraction of full load KVA where efficiency peaks.

- is full load copper loss.

- is iron loss.

At fraction of full load, copper losses equal ², and iron losses are . For maximum efficiency, copper losses equal iron losses.

To express in terms of and :

- The fraction of full load KVA () at maximum efficiency is the square root of the ratio of iron losses to full load copper losses.

So, the transformer operates most efficiently at this specific fraction of full load KVA. Plugging the value of into the equation confirms the condition for maximum efficiency.

All-Day Efficiency of a Transformer

Distribution transformers work 24 hours a day with varying loads, unlike power transformers. Their efficiency over a full day is called all-day efficiency. This is the ratio of total energy output to total energy input over 24 hours. All-day efficiency, generally between 90-94%, considers both loaded and no-load periods.

The load cycle affects this efficiency, as transformers rarely operate at full load and often run between 50-75% of rated capacity. Unlike commercial efficiency, which measures output to input power at full load, all-day efficiency better reflects performance under real conditions. Distribution transformers have constant iron losses and variable copper losses. Iron losses stay the same all day, depending on voltage and frequency, while copper losses change with the load.

All-day efficiency gives a realistic view of performance because it factors in the energy used and delivered over a 24-hour period. To ensure safe continuous operation, distribution transformers keep flux densities and currents lower, which improves all-day efficiency but lowers peak efficiency.

How to Make a Transformer More Efficient

You can improve transformer efficiency through specific design and manufacturing techniques:

- Use high-grade silicon steel with low losses for the core. This helps reduce hysteresis and eddy current losses.

- Keep flux density low by providing enough core cross-sectional area and weight.

- Design the winding with minimal overhangs and gaps to reduce stray flux and losses.

- Use high-conductivity annealed copper in the windings to lower resistance.

- Impregnate the windings with high-quality insulating oil, such as transformer oil, to cut down on dielectric and corona losses.

- Choose an effective cooling method like ONAN or ONAF to manage hot-spot temperatures and winding resistance.

- Apply strict manufacturing tolerances and quality controls for close coupling between primary and secondary coils.

- Choose the correct transformer rating based on maximum efficiency to reduce losses.

- Use advanced materials like amorphous steel or high-temperature superconductors for extra efficiency gains.

Conclusion

With a growing focus on saving energy and reducing grid losses, transformer efficiency has become more important. The way we design, select, and load distribution transformers affects transmission and distribution losses. Power utilities now choose and upgrade transformers that meet strict BIS, IEC, or IEEE standards for efficiency. Highly efficient transformers help cut yearly energy costs and last longer by reducing thermal strain. This article covers key details about transformer efficiency to support your AE, JE, and ESE exam preparation.

FAQs

What is the formula for transformer efficiency?

First, find the full load copper loss in the windings and the core loss in the core. Add these together to get the total loss. Then, calculate efficiency using the formula: efficiency = (output / (output + loss).

Why isn’t a transformer 100% efficient?

Transformers contain copper windings, and copper has resistance like all materials. This resistance causes some electricity to turn into heat, which reduces the transformer’s efficiency to less than 100%.

How do you check a transformer’s efficiency?

The turns ratio test is a common way to check the winding ratio between the primary and secondary coils of a transformer. This test helps confirm that the transformer has the correct ratio of primary to secondary turns.

What is the efficiency of a 3-phase transformer?

Transformers are among the most efficient electrical devices. Most have a full load efficiency between 95% and 98.5%.

Read More – MHD Generation: Revolutionizing Energy Production