To perform a safe pump down and pump out on chillers, isolate the system, recover the refrigerant carefully, and use proper tools. Always follow safety guidelines and double-check connections. This protects your chiller, the environment, and ensures smooth maintenance.

This article aims to educate people on how to effectively pump down and pump out a chiller, in order to reduce cost and prevent problems. So, it is not so much following procedures, as it is safeguarding your gear, keeping yourself out of harm’s way, and catering for your system’s longevity in mind.

Tune in to know the detailed easy guidelines for a safe pump down and pump out in chillers. We shall help you in the process keeping your system productive, secure and prepared for functionality throughout the period.

Tools and Safety Precautions

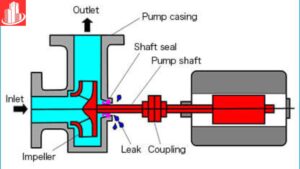

Pump down and pump out operations must be done effectively on chillers which means that there are things that need to be done in preparation to the operation. Equipment include manifold gauges, refrigerant recovery machine, recovery cylinders and pressure temperature chart. Such tools make sure that the pressure is well measured, the refrigerant is transferred effectively, and all policies followed. Wearing gloves, protecting eye wear and appropriate working dress code is essential to reduce chances of risk exposure.

Safety measures are critical. Electrical isolation must be done before starting any operation on the chiller in order to avoid any form of accidental switch on of the appliance. Make sure the working area is well ventilated so that piling up refrigerants is not a health issue. Both regarding personnel and environmentally, principles relating to the handling and disposal of refrigerants should also be complied with.

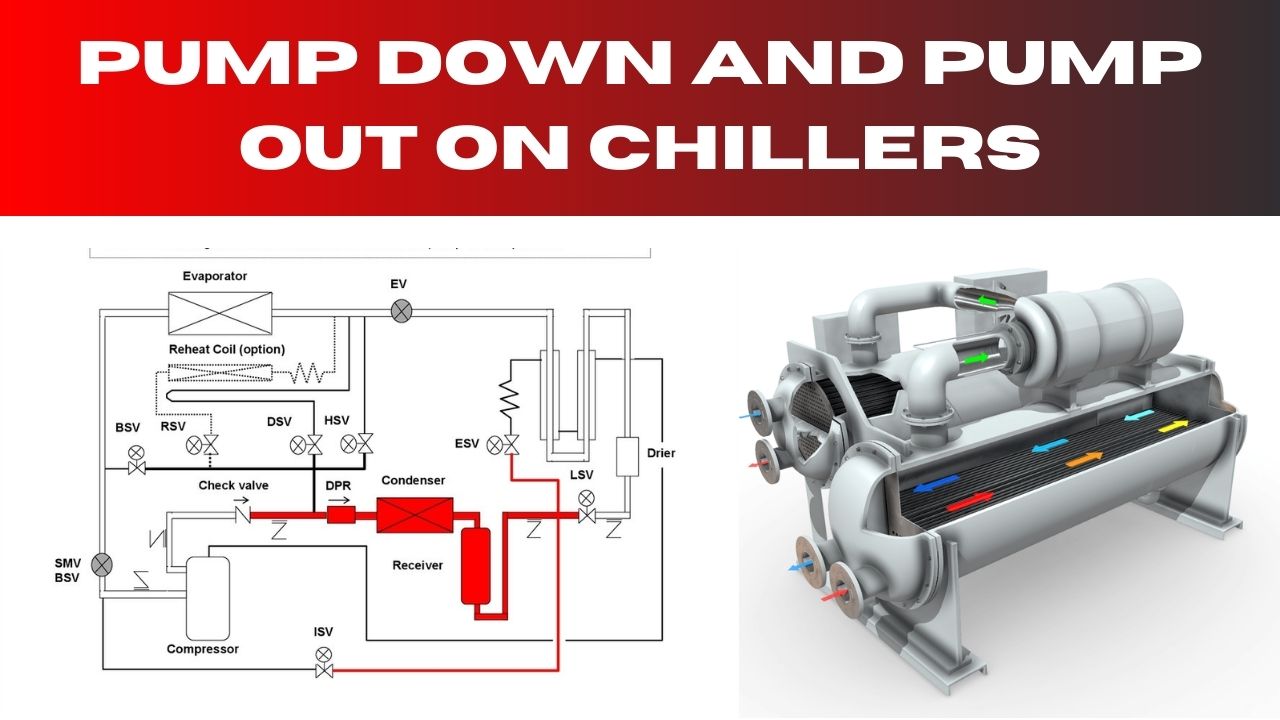

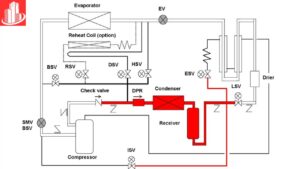

Understanding the Pump Down Process

The pump down procedure causes refrigerant to stagnate in the high pressure areas like the condenser/ receiver hence is a must do each time there is a need to work on the system. This procedure also helps avoid any losses or even contamination of the refrigerant that may not be necessary.

The process starts by connecting manifold gauges to the service ports of the chiller. The high pressure side of the circuit is connected to the condenser while the low side of the circuit goes to the evaporator. Following this working, the compressor is turned on for a short time in order to pump the refrigerant from the evaporator to the condenser. Although not usually explored extensively in this stage, pressure readings are taken constantly to check on how the operation is developing.

Completing the Pump Down

As the low-side pressure approaches zero psi, the suction service valve is closed to seal the refrigerant within the high-pressure side of the system. This step is critical to prevent refrigerant backflow into the evaporator. Once the refrigerant is isolated, the compressor and the entire system are powered down completely.

A proper pump down means that the refrigerant is contained to allow the maintenance and repairs to be done without any concern because even leakage and the general system can be compromised. Properly sealing the system at this stage prevents unnecessary operational interruptions.

Conducting the Pump Out Process

The pump out process is used when refrigerant needs to be entirely removed from the chiller, often for extensive repairs or system replacement. This procedure requires careful handling and adherence to regulations to avoid refrigerant loss or environmental harm.

The recovery machine is set up by connecting it to the chiller’s service ports. A hose is connected to both the condenser and the recovery cylinder so that the vapor enters and exits the former only. Resetting the system, first, means clearing the hoses of any trapped air which could greatly hinder the process.

Steps to Ensure Effective Recovery

Activate the Recovery Machine:

- Turn on the recovery machine to begin transferring refrigerant from the chiller to the recovery cylinder.

Monitor the Process:

- Keep a close eye on pressure gauges to track the system’s status throughout the operation.

- Check the recovery cylinder’s weight regularly to prevent overfilling.

Complete the Recovery:

- Allow the process to continue until both high-side and low-side pressures reach atmospheric levels or the specified vacuum.

Shut Down and Disconnect:

- Turn off the recovery machine once the process is complete.

- Carefully disconnect all hoses and equipment from the system.

Safely Store Refrigerant:

- Finally make sure you get the recovered refrigerant right back into the cylinder for reuse or disposal depending on the regulation of your country.

Key Considerations for Safe and Efficient Handling

To enhance the safety and efficiency of the pump out process, it is essential to follow best practices:

- Purge Air from Hoses: This is good because it helps in controlling the trapped air in order to enhance the correct transfer of refrigerant and to also remove contaminants.

- Monitor Cylinder Capacity: Avoid overfilling cylinders by tracking their weight during the recovery process.

- Use Approved Recovery Cylinders: Ensure that the cylinders used are clean and suitable for the type of refrigerant that is to be used so as to avoid cross connection.

- Follow Environmental Regulations: Always observe the regulatory laws of the country as far as refrigerant handling, storage and disposal as there are legal repercussions that one can face when penalized.

Through these measures, technicians will be in a safe position to guarantee clients of a fast and efficient pump out service.

Leak Detection and System Testing

Leak detection is the final step followed after pump down or pump out through recommissioning of the system. There are other acceptable methods that can be used to detect leaks in the system; they include the use of electronic leak detectors or even a solution flooded with soapy water can be used. Such leakage should be fixed as soon as possible to avoid compromising the efficiency of the developed system.

After leak testing, the system is taken through vacuuming to ensure it is free from air as well as moisture. This creates good conditions for recharging of the refrigerant. A thorough evacuation also helps maintain efficiency and extends the lifespan of the system components.

Refrigerant Recharging and System Restart

The last step of recommissioning the chiller is to recharge the refrigeration system with the correct type of refrigerant. Correct proportions and type of refrigerant as recommended by the manufacturer are used in the system as a circuit. This step is very crucial in order to ensure the right cooling performance is achieved.

After recharging, the chiller is restarted, and its operation is monitored closely. Technicians should observe pressure and temperature readings, ensuring they align with standard operating parameters. The only way to affirm proper operation at this point is to make sure the chiller is in good standing to go on doing its tasks without fear of low efficiency or breakdowns.

Ensuring Longevity and Reliability

The siphon down and siphon out techniques are key pieces of chiller support. Legitimate execution guarantees the utilization of right devices and strategies. Keeping up with chillers and taking care of refrigerants accurately expand chiller life. These practices additionally decrease natural dangers and guarantee consistence with guidelines.

By following these techniques, professionals can work in a more secure and cleaner climate. Dominating abilities like siphon down and siphon out is fundamental for upkeep. Utilizing the right devices and keeping wellbeing rules guarantees powerful tasks. Customary upkeep expands the chiller’s life expectancy and lessens natural effect. Legitimate refrigerant taking care of additionally guarantees consistence with industry guidelines.

Conclusion

Mastering how to perform a safe pump down and pump out on chillers is essential for efficient maintenance and long-lasting performance. These processes help your chiller run leak- and damage-free, helping your system remain efficient and environmentally sound. This means that by adhering to operational safety procedures and swiftly handling refrigerants, you stand to not only save the planet, but also boost serving capacity of equipment.

The knowledge of how to perform a safe pump down and pump out on chillers gets you familiar with the maintenance job regardless of the kind of job you are to do. Performing these steps correctly is beneficial in that it only takes less time and less money while maintaining the chillers properly. When properly maintained and monitored, the chiller will remain in a good state of health to deliver the best at all times for many years. Maintenance done right is always worth the effort!

FAQs

How do you pump down a chiller system?

To pump down a chiller system, turn the refrigerant off by closing the service valve. Following this, turn the compressor in order to circulate the refrigerant, towards the receiver or condenser. Monitor pressure to avoid overloading.

What is the difference between pump down and pump out?

Pump down stores refrigerant in the system’s condenser or receiver when used as a command and pump out means all refrigerant must be taken for repairing or servicing. Both are essential but serve different purposes.

What are the safety controls on chillers?

Chiller safety controls include pressure switches, flow sensors, and temperature limits. They protect the system from high pressure, low flow, or overheating. Regular checks ensure reliability.

What is the pump down process?

The pump down process is the process by which refrigerant is moved from the evaporator to the condenser. It isolates refrigerant for safe repairs. This prevents leaks and keeps the system ready for use.

What is blowdown in chiller?

Blowdown in chillers removes concentrated water impurities. This process helps maintain water quality and prevents scale buildup. It improves efficiency and protects the system.

Also Read This Article : How Buffer Tanks Work: A Complete Guide to Their Operation