- Supply air duct –

The duct which supplies the conditioned air from the air conditioning equipment to the space to be cooled is Called supply air duct.

- Return air duct –

The duct which carries the reciprocating air from the conditioned space back to the air conditioning equipment is called return air duct.

- Fresh air duct –

The duct which carries the outside air is called fresh air duct.

- Low pressure duct –

When the static pressure in the duct is less than 50 mm of water gauge, the duct is said to be a low pressure duct.

- Medium pressure duct –

When the static pressure in the duct is up to 150 mm of water gauge, the duct is said to be a medium pressure duct.

- High pressure duct –

When the static pressure in the duct is from 150-250 mm of water gauge, the duct is said to be a high pressure duct.

- Low velocity duct –

When the velocity of air in the duct is up to 600 m/min, the duct is said to be a low velocity duct.

- High velocity duct –

When the velocity of air in the duct is more than 600 m/min, the duct is said to be a high velocity duct.

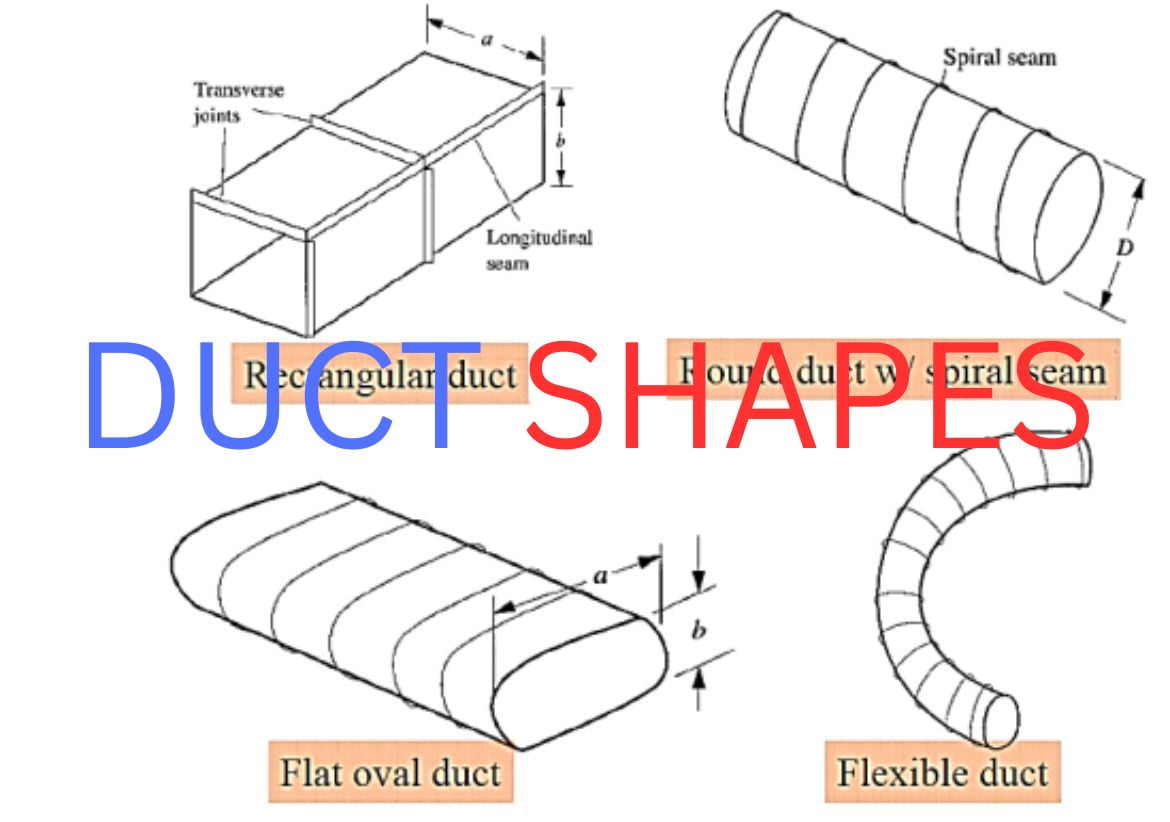

- Circular/round duct:-

For a definite cross-sectional area and mean air velocity, a circular duct has less fluid resistance against air flow than other ducts. It also has better stiffness and strength.

- Rectangular duct:

Rectangular duct takes less space as compared to the round duct. It can be easily fitted where space is less. Rectangular ducts are less stiff than circular ducts, and also easily fabricated.

- Flat oval duct:

Flat oval ducts have a shape between round and rectangular cross-sectional shown in Flat oval duct have the benefits of both the rectangular and the round duct with less large-scale air disorder and a lesser depth of space required

- Flexible duct:

Flexible ducts are used to connect the key duct to the incurable (terminal) box. Their plasticity and ease of elimination allow separation and rearrangement of the incurable (terminal) devices. These ducts are made of numerous-ply polyester film reinforced by a helical steel wire core.