MHD generation converts hot and moving gaseous or liquid substances in a magnetic field into electricity. This application is considered revolutionary since it delivers energy output more efficiently and with minimal parts hence safer and less costly in terms of maintenance.

What if we can produce electric energy without noisy machines or rotational structures such as turbines? Magnetohydrodynamic (MHD) generation does this by utilizing hot gasses and magnetic fields, making the generation of energy cleaner, quieter and more efficient for all.

Please remain with us while we take you through the rather interesting topic on MHD generation. Learn how this exciting new technology can alter how the world will generate power in the future, and how it will do so more sustainably. Please follow this blog and become a part of our journey towards a better and a more sustainable tomorrow!

The principles of MHD Generation

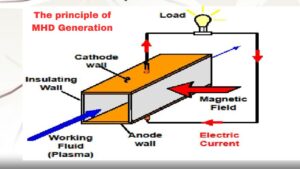

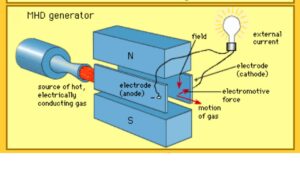

MHD power generation is a process in which thermal and kinetic energy are converted into electrical energy with the use of magnetic fields without the use of rotating parts. The key concept relies on the flow of an electrically conducting fluid: a plasma being usually the most liquid of all four states of matter. A cyclic interaction is created here that produces a force lying in a plane perpendicular to both the magnetic field and the direction of fluid flow that makes the fluid conduct electricity. This electric current can then be collected using electrodes placed along the channel, allowing for efficient power production.

The use of plasma as a working fluid is essential for maintaining conductivity at high temperatures. The high thermal energy helps sustain ionization levels, which is necessary for the continuous flow of electricity. This method allows Magnetohydrodynamic generators to operate at much higher temperatures than conventional power plants, resulting in higher theoretical efficiencies. Unlike turbines that require mechanical rotation, MHD generators are built for seamless energy conversion, reducing the chances of mechanical failures and minimizing maintenance needs.

MHD Generators Operate

MHD generators operate on electromagnetic induction which was introduced by Faraday. In these systems, the conducting fluid will stream through the channel with the presence of a magnetic field. As it moves, the magnetic field together with the flow of the fluid causes an electric current—that which flows perpendicular to the fluid and the field of magnet. The current is hereby sensed by the electrodes that are placed along the channel walls and is made available for the utilization in external circuits for electrical purposes.

The design of MHD generators can vary between linear and disk configurations. In the linear type, the conducting fluid flows in a straight path through a rectangular channel, while in the disk type, the fluid moves radially outward across a disk-shaped plane. Both designs harness the same electromagnetic principles but have distinct structures to optimize for different types of power outputs. These systems, free from moving mechanical parts, ensure smoother operation and potentially longer lifespans.

Types of MHD Systems

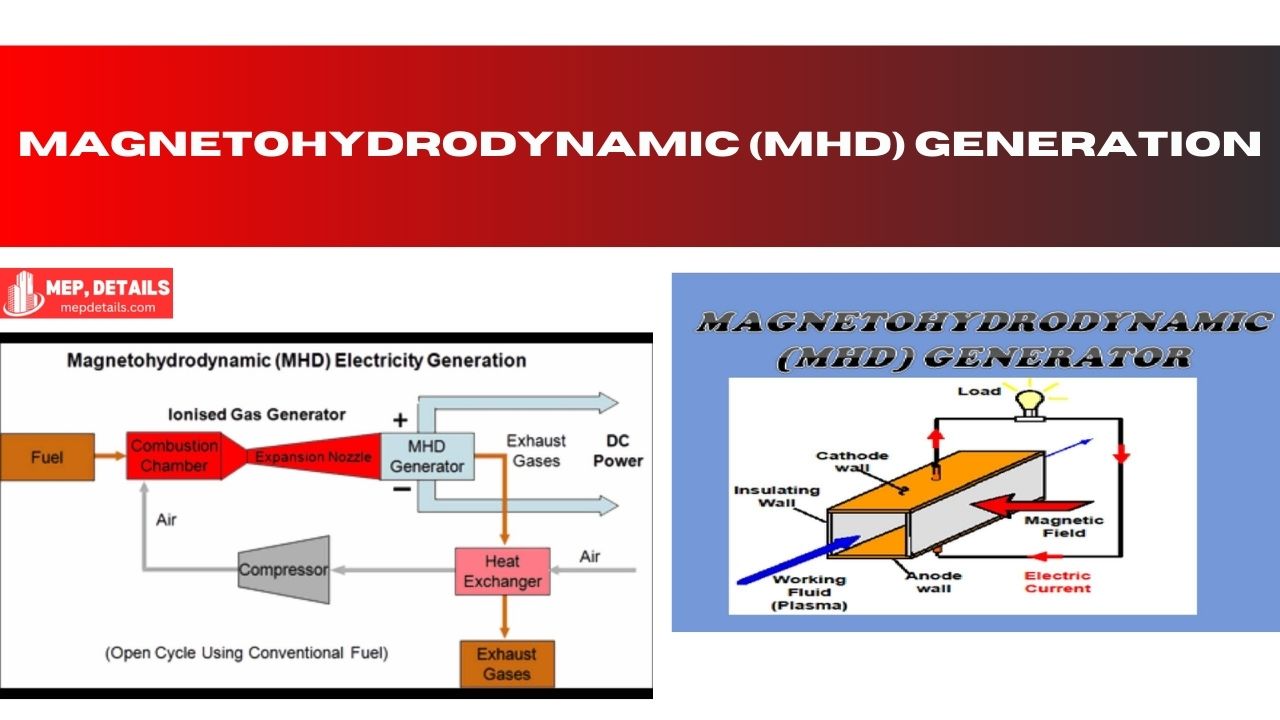

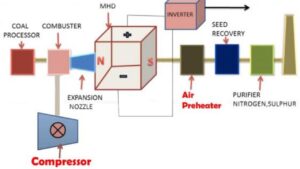

MHD generation systems are broadly categorized into three main types: They are; open cycle, closed cycle and liquid metal MHD systems. They both have blend of properties designed for various uses and performances.

Open Cycle MHD Systems:

This system employs the by-products of fossil fuel combustion in generating a high temperature ionized gas. Plasma flows through the MHD generator,((‘Plasma is taken through a set of Magnetohydrodynamic generators:)), interacts with the magnetic field to produce electricity. Compared to closed cycle systems are comparatively easy to design and implement and are relatively fast to deploy. However, its biggest disadvantage is the exhaust heat loss the gasses take with them when expelled out of the engine which lowers the overall efficiency and is not environmentally friendly.

Closed Cycle MHD Systems:

Closed cycle systems for the contrary use helium or argon – noble gasses that are ionized externally and circulated within the cycle. This lowers the environmental load for BIPV and optimizes the receiving surface to capture energy. Exterior design, which is an aspect of the paper’s closed-loop design concept, can accommodate heat recovery systems hence increasing efficiency and sustainability. Several of these systems are long-term and costly in the short term but result in more lasting efficiencies and less pollution.

Liquid Metal MHD Systems:

Liquid metal MHD frameworks, still generally trial, may involve potassium or sodium as the conductive material. Metals offer preferred conductivity and thickness over glasses, making these frameworks more reduced and possibly more effective. The Joule warming between the streaming fluid metal and the attractive field produces huge electrical outcomes. Therefore, these frameworks are supposed to have a promising future. Their superior exhibition potential makes them a thrilling region for additional turn of events.

Advantages of MHD Generation

One of the primary advantages of MHD power generation is its high theoretical efficiency. MHD systems can achieve higher operational temperatures than conventional steam turbines, which are limited by the Carnot cycle. This allows MHD generators to convert thermal energy into electrical energy more effectively, with potential efficiencies exceeding 50%, compared to the 30-40% range typically seen in conventional plants.

Magnetohydrodynamic (MHD) frameworks offer a few benefits, including quicker response and caution rates. Not at all like turbine frameworks, MHD frameworks can be brought on the web and taken disconnected all the more rapidly. This makes them ideal for top burden power stations. While MHD frameworks have striking advantages, they additionally accompany specific downsides. Their capacity to answer quickly adds to their effectiveness in overseeing energy requests.. Furthermore, the MHD generator does not contain any moving mechanical parts, which makes the system more reliable than mechanical systems. This leads not only to lesser maintenance expenditure but also increased durability for the good, thus a longer life cycle.

Lack of Development Constraints MHD Technology

However, MHD power generation has some drawbacks that have inhibited its integration into mainstream power generation. But one of the serious problems is that the operating temperatures for plasma conductivity can approach extremely high levels. These temperatures impose great stresses on the ability of materials in Magnetohydrodynamic working generators to withstand exposure without degradation.

A significant test is material disintegration, especially on the terminals. This can abbreviate the life expectancy of MHD devices and increment support costs. In addition, losses through radiation are also possible at these high temperatures, which will further lower the system’s efficiency. It is hence plausible that meeting these challenges by applying achievements in material science and engineering will extend the comprehensiveness of this type of MHD as a viable energy solution.

Cost and Economic Factors

Economic issues are particularly problematic when examining MHD power generation. Superconducting magnets required to generate the very strong magnetic fields necessary for Magnetohydrodynamic systems are capital intensive as well. Furthermore, the process of applying potassium or cesium for boosting conductivity of the plasma also incurs a great expense during the construction of MHD systems.

| Cost Factors | Impact on MHD Systems |

| Superconducting Magnets | High initial cost; critical for magnetic fields |

| Ionizing Agents (e.g., cesium) | Expensive; boosts plasma conductivity |

| Material Costs | High due to temperature-resistant materials |

| Maintenance Expenses | Lower than traditional systems but still notable due to material erosion |

Research and development aimed at reducing these costs and finding cost-effective alternatives are ongoing. Innovations in magnet technology, such as high-temperature superconductors, have the potential to lower expenses and improve the economic outlook for Magnetohydrodynamic systems. Until these technologies become more accessible and affordable, the large-scale adoption of MHD generation will be limited.

Recent Advancements in MHD Technology

Recent advancements in MHD technology have focused on overcoming the primary challenges related to efficiency and cost. Superconducting magnets have been a major area of research, with the goal of creating strong magnetic fields without excessive power consumption. The development of more effective magnets can lead to higher power outputs and enhanced performance of Magnetohydrodynamic systems.

Material advancements are also playing a crucial role in the progress of MHD technology. New high-temperature resistant materials and protective coatings are being developed to prevent electrode erosion and withstand harsh operational conditions. These advancements are essential for extending the lifespan of Magnetohydrodynamic generators and minimizing maintenance needs, making them more competitive with traditional power generation methods.

Future Prospects of MHD Generation

The fate of MHD age looks encouraging as it very well may be synchronized with other sustainable power sources. By incorporating MHD frameworks with geothermal power plants, mixture arrangements can be created. These frameworks can tackle high temperatures from inexhaustible hotspots for direct power age. This approach likewise guarantees energy creation without CO2 outflows. The above applications conform to initiatives towards sustainability and minimal usage of fossil fuels that are current worldwide.

The two major themes will be increased corporation research investment and government promotion. As the primary means by which the growth and adoption of Magnetohydrodynamic technology will be driven. As there is gradual advancement in material science, magnet technology and other overall system designm. MHD generation may emerge as an integral component in generation maps. The outcome from this innovation might spur the generation of new cleaner power that can reduce electricity’s carbon footprint of the electrical energy we are using today.

Conclusion

MHD Generation: Revolutionizing Energy Production acts as a new and revolutionary way of generating electrical power. Due to the application of principles from the field of magnetohydrodynamics. This technology suggests such advantages as greater efficiency and decreased material and service requirements, as well as the utilization of a new type of energy. Recent years design improvements of solid materials and magnets make MHD systems more practical for commercial application.

As we look toward the future, embracing MHD Generation: Revolutionizing Energy Production could take us closer to a sustainable world. The author of the article said: Standalone Magnetohydrodynamic when connected to renewable energy sources forms hybrid systems that have small or negligible impact on the environment while giving high efficiencies. Some of the challenges that are likely to face in future will be put into consideration by the continued research and development. In order to make MHD generation play a significant role in the energy sector in the future. As one, let us build a future here in Quest for sustainable, less complex energy solutions.

FAQs

What does MHD stand for in the energy field?

MHD stands for Magnetohydrodynamics, the study of electrically conducting fluids in magnetic fields. It is particularly important for understanding energy generation processes.

What is the fuel in the MHD generator?

An MHD generator uses ionized gases or plasmas created from combustion gases as fuel. Ionizing agents like potassium or cesium are added to improve conductivity.

What is the working principle of MHD accelerator?

An MHD accelerator propels a conductive fluid by passing it through a magnetic field, which induces an electric current. This interaction between the fluid’s motion and the magnetic field generates energy.

What are the advantages of MHD generation?

MHD generation offers high efficiency and minimal mechanical wear as it has no moving parts. It also provides rapid response times and can reduce emissions when combined with renewable energy sources.

What is the basic principle of MHD generation?

MHD generation works by converting thermal and kinetic energy into electrical energy. It uses the interaction between a moving conductive fluid and a magnetic field to create an electric current. This process efficiently induces power without mechanical moving parts.

Also Read It : Power Plant: Types, and Their Role in Modern Energy Production