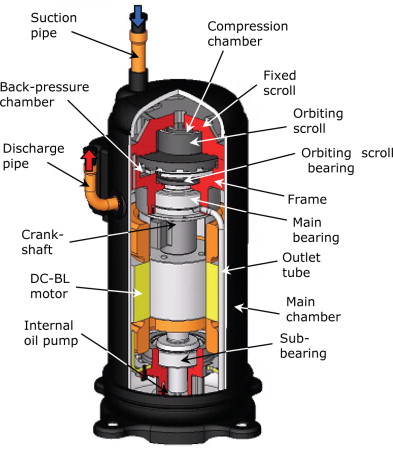

Scroll Compressor-

Scroll compressors compress the refrigerant by nesting two offset spiral disks। The upper disk remains stationary, while the lower disk moves in orbital mode

Scroll compressors are the most efficient type of compressors, with few moving parts and a quiet, smooth operation.

A rotary-scroll compressor is used via a fixed and orbital scroll to compress larger volumes of gaseous refrigerant to higher pressure and temperature.

Automobile air conditioning systems and commercial chillers use scroll compressors.

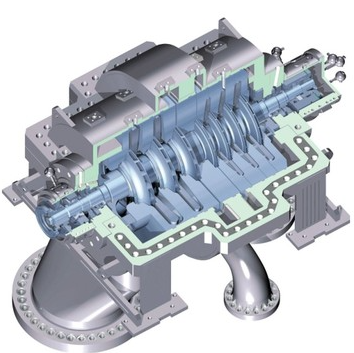

Centrifugal Compressor–

Centrifugal compressors exert centrifugal force on refrigerant inside a volute or round chamber through the rotating action of an impeller wheel.

Centrifugal compressors have fixed volume chambers, not the positive displacement principle.

They are ideal for compressing high amounts of refrigerant to comparatively low pressures। Because impeller wheels produce small compressive forces, centrifugal compressor systems usually use two or more impeller wheels in series to produce high compressive forces.

When operating in multiple stages, centrifugal compressors are ideal because they have a simple design, few moving parts, and high energy efficiency.

Open type compressor–

The motor is connected to the compressor by a belt or crankshaft।

Open-type compressors are the most vulnerable to leaks, so they are not leak proof

They rely on shaft seals to keep working fluids from leaking and to keep the internal pressure up in this types, compressor and motor are separate units with their own casing.

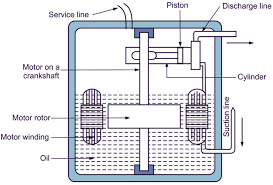

Hermetic ( Sealed Type) Compressor–

In hermetic compressors, the compressor and motor are enclosed in the same housing so that refrigerant does not leak out

The housing has welded connections for both the power input socket and the refrigerant inlet and outlet

As a consequence of this, there is almost no chance of refrigerant leakage from the compressor

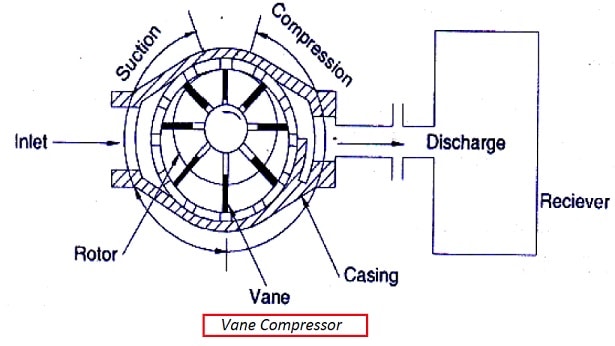

Rotary Vane Compressor–

A rotary-vane compressor has a function similar to that of a piston, so it is also called a rotary-piston compressor

In this cylinder is a fixed casing। The space between the cylinder and the rolling piston is divided into two parts (suction and discharge) by the vane

Gas suction, compression, and discharge are achieved by increasing and decreasing these two volumes as the rolling piston rotates

Drive speed (constant or variable) and number of vanes can divide this type of compressor into different groups

Each working cycle has five actions: start, suction, compression, discharge, and end.

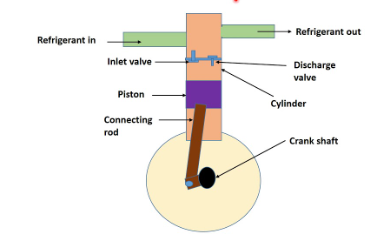

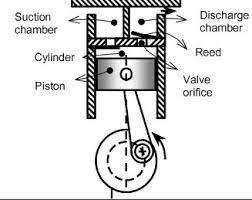

Reciprocating Compressor–

A reciprocating compressor, also known as a piston compressor, uses the back-and-forth piston motion in a cylinder in conjunction with suction and discharge valves to compress the vaporized refringent from a low pressure and temperature to a high pressure and temperature.

A crankshaft converts motor rotations into piston reciprocations to move the piston.

Suction, compression, and discharge are the three action in each operation cycle। As a result, these three actions can be performed by each crankshaft rotation in sequence। Vibration is caused by gas displacement that is discontinuous.

1 thought on “HVAC Types of Compressor Explained”