Introduction

The ductwork is an essential component of any HVAC (heating, ventilation, and air conditioning) system that helps distribute conditioned air throughout a building. Appropriate Duct sizing affects interior air quality, guarantees proper airflow distribution, and increases energy efficiency. The significance of appropriate duct sizing and the associated computations are examined in this article.

Basic Definitions-

- cfm: volume of air flow; cubic feet/minute

- SQ FIT duct size or cross-sectional area; square feet Air volume in cfm can be calculated by multiplying the Air velocity by the cross-sectional area of the duct in square feet.

- cfm = fpm x Area Given any two of these three quantities, the third can be readily determined:

- fpm = cfm/area

- Area = cfm/fpm

TYPES OF DUCT SHAPES

Ducts commonly used for carrying air are of round, square, or rectangular shape. All have advantages and disadvantages, and find applications where one is definitely superior to the other

Round Duct

The Duct shapes of Due to its large cross-sectional area and small contact surface, the round duct design is the most effective (provides the least resistance) for transporting moving air. Put another way, for the same amount of air handled, it requires less material than square or rectangular ducts. For example, the air-carrying capacity of a 26″ x 11″ rectangle duct is equal to that of an 18 inch diameter duct. The rectangular duct has a perimeter of 6.2 feet and an area of 286 square feet, while the round duct has a cross-sectional area of 254.5 square inches and a perimeter of 4.7 feet. Because of this, the rectangular duct contains 32% more metal and would therefore be more expensive. Additionally, there is more manpower, supports, and insulation.

| Airflow (CFM) | 4″ Diameter | 5″ Diameter | 6″ Diameter | 7″ Diameter | 8″ Diameter | 9″ Diameter | 10″ Diameter |

|---|---|---|---|---|---|---|---|

| 0-50 | – | 4 | 4 | 5 | 5 | 6 | 6 |

| 51-100 | 4 | 5 | 5 | 6 | 6 | 7 | 8 |

| 101-150 | 5 | 6 | 6 | 7 | 8 | 9 | 10 |

| 151-200 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 201-250 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 251-300 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 301-400 | 9 | 10 | 11 | 12 | 14 | 15 | 16 |

| 401-500 | 10 | 11 | 12 | 14 | 15 | 17 | 18 |

| 501-600 | 11 | 12 | 14 | 15 | 17 | 18 | 20 |

| 601-700 | 12 | 14 | 15 | 17 | 18 | 20 | 21 |

| 701-800 | 14 | 15 | 17 | 18 | 20 | 22 | 23 |

| 801-900 | 15 | 17 | 18 | 20 | 22 | 24 | 25 |

| 901-1000 | 17 | 18 | 20 | 22 | 24 | 26 | 27 |

Rectangular Ducts

The Rectangular Ducts that are square or rectangular fit well with the design of buildings. They are significantly simpler to install between joists and studs and fit into walls and above ceilings. When space constraints force the use of rectangular ducts, maintain a low width-to-height ratio (also known as the aspect ratio). In terms of air conveyance efficiency, the most optimal rectangular duct form is one with an aspect ratio near to 1. A duct that has an aspect ratio greater than 4 uses material far less effectively and loses a lot of pressure. When trading off additional duct cost of material and fan energy for headroom savings, aspect ratios of two to three are optimal.

| Airflow (CFM) | 8″x4″ | 10″x6″ | 12″x6″ | 14″x8″ | 16″x8″ | 18″x10″ | 20″x10″ | 24″x12″ |

|---|---|---|---|---|---|---|---|---|

| 0-50 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 |

| 51-100 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 101-150 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 14 |

| 151-200 | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 15 |

| 201-250 | 8 | 9 | 10 | 11 | 12 | 14 | 15 | 17 |

| 251-300 | 9 | 10 | 11 | 12 | 14 | 15 | 17 | 18 |

| 301-400 | 10 | 11 | 12 | 14 | 15 | 17 | 18 | 20 |

| 401-500 | 11 | 12 | 14 | 15 | 17 | 18 | 20 | 22 |

| 501-600 | 12 | 14 | 15 | 17 | 18 | 20 | 22 | 24 |

| 601-700 | 14 | 15 | 17 | 18 | 20 | 22 | 24 | 26 |

| 701-800 | 15 | 17 | 18 | 20 | 22 | 24 | 26 | 28 |

| 801-900 | 17 | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| 901-1000 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 |

Oval Duct

The majority of the benefits of round ducts are retained by flat oval ducts, which have lower height requirements. Fittings for flat oval ducts are challenging to make or alter in the field, though. Additional drawbacks consist of:

1. Difficulty in handling and transporting larger diameters;

2. Propensity of these ducts to round out under pressure; and

3. Difficulty in installing oval slip joints in large aspect ratios.

| Airflow (CFM) | 3″x8″ | 4″x10″ | 4″x12″ | 5″x12″ | 5″x14″ | 6″x14″ | 6″x16″ | 7″x18″ | 8″x20″ |

|---|---|---|---|---|---|---|---|---|---|

| 0-50 | 3 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 |

| 51-100 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 9 |

| 101-150 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 9 | 10 |

| 151-200 | 5 | 6 | 6 | 7 | 7 | 8 | 9 | 10 | 11 |

| 201-250 | 6 | 6 | 7 | 7 | 8 | 9 | 10 | 11 | 12 |

| 251-300 | 6 | 7 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 301-400 | 7 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 401-500 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 501-600 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 601-700 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 701-800 | 9 | 10 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 801-900 | 10 | 11 | 12 | 13 | 14 | 16 | 17 | 18 | 19 |

| 901-1000 | 10 | 12 | 13 | 14 | 15 | 17 | 18 | 19 | 20 |

Velocity Method for Round Ducts:

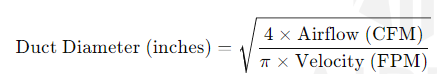

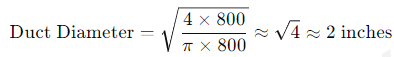

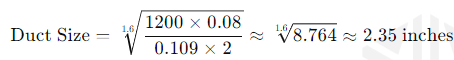

The formula for calculating the diameter of a round duct based on airflow (CFM) and velocity (FPM) is:

Example: Let’s say we have an airflow of 800 CFM and want to maintain a velocity of 800 feet per minute (FPM) in a round duct. Using the formula:

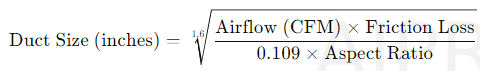

Friction Loss Method for Rectangular Ducts:

The formula for calculating the size of a rectangular duct based on airflow (CFM), friction loss (inches of water gauge per 100 feet), and aspect ratio (ratio of width to height) is:

Example: Suppose we have an airflow of 1200 CFM, a friction loss of 0.08 inches of water gauge per 100 feet, and an aspect ratio of 2:1 for a rectangular duct. Using the formula:

These formulas serve as a foundation for duct sizing calculations, but it’s important to remember that actual duct sizing may involve more intricate calculations that take into account elements like system design, fittings, and duct material. In practical applications, professional HVAC engineers usually employ detailed guides or specialized software for proper duct sizing.

You can Also read Duct Surface Area Calculation click here

Good and so helpful