A thermoelectric generator (TEG), also known as a Seebeck generator, changes heat directly into electrical energy using the Seebeck effect. TEGs use temperature differences to produce power, similar to a heat engine, but they are more compact and have no moving parts. They are generally more expensive and less efficient than other options. When the process is reversed, it becomes a thermoelectric (or Peltier) cooler, creating a heat gradient with an electric current. This guide will cover how thermoelectric generators work, the materials used, their advantages and disadvantages, and where they are commonly applied.

How Thermoelectric Generators Work

Thermoelectric generators (TEGs) are solid-state devices made from semiconductor materials that turn heat and temperature differences into direct current (DC) power. They use the Seebeck effect, which generates a voltage when there is a temperature difference. This voltage drives an electric current, which powers devices.

A thermoelectric generator differs from a thermoelectric cooler (also called a TEC, Peltier module, cooling chip, or solid-state cooler). A thermoelectric cooler works in the opposite way. When you apply a voltage to a thermoelectric cooler, it creates an electric current that moves heat from a cooler side to a warmer side using the Peltier effect. Though both are solid-state semiconductor devices with similar parts, their designs often vary.

Thermoelectric generators focus on generating power, while thermoelectric coolers (or Peltier coolers) work to manage heat. You can find thermoelectric coolers in applications like cooling, heating, refrigeration, and temperature control. The rest of this explanation will focus on thermoelectric generators.

How does a Thermoelectric Generator utilize the Seebeck Effect?

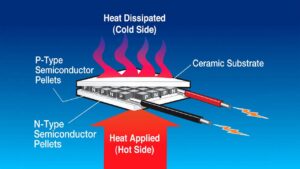

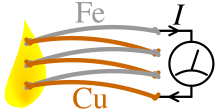

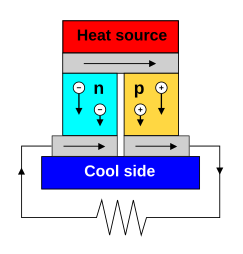

A thermoelectric generator uses thermocouples as its main parts. Each thermocouple has two semiconductors—one p-type and one n-type—that are joined by a metal strip to form an electrical connection in a series. These semiconductors, also called thermoelements, dice, or pellets, play a key role in creating electricity from heat.

The Seebeck effect allows heat energy to directly turn into electrical voltage. This effect happens when charge carriers inside the semiconductors move. In n-type semiconductors, electrons act as charge carriers, while in p-type semiconductors, holes act as charge carriers. These carriers move from the hot side of the semiconductor to the cooler side, gathering at one end. This gathering of charge creates a voltage that matches the temperature difference across the semiconductor.

Semiconductor Materials used for Thermoelectric Generators

Thermoelectric generators commonly use three types of materials: bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon germanium (SiGe). The choice of material depends on the heat source, the cold sink, and the design of the generator. Although researchers are studying many other materials for thermoelectric generators, they are not yet available for commercial use.

What is a Thermoelectric Generator Module?

A thermoelectric generator module uses many p-type and n-type couples, which are connected in series or parallel to produce the needed electrical current and voltage. These couples sit between two flat ceramic plates. The plates give the module strength, provide a flat surface for mounting, and prevent electrical short circuits with their insulating layer.

Advantages of Thermoelectric Generators

Thermoelectric generators offer several advantages. They are highly reliable because they are solid-state devices with no moving parts, which means they rarely break or wear out. For example, the thermoelectric generator on the Voyager 1 spacecraft has run continuously for over 41 years, traveling more than 13 billion miles without any need for maintenance.

These generators can also be completely silent, unlike some other power sources. They don’t produce greenhouse gases, which makes them more environmentally friendly than certain other energy conversion technologies. Thermoelectric generators can use a wide range of fuel sources to create the required heat, providing greater flexibility compared to technologies with fuel restrictions.

In addition, thermoelectric generators are highly scalable, producing power levels that range from tiny microwatts to large kilowatts. They work in any orientation, unlike some systems that need specific positioning relative to gravity. They also function well in both zero-G and high-G environments, where other technologies may struggle.

Thermoelectric generators directly convert heat into electricity, which simplifies their design and reduces energy loss since they avoid the intermediate mechanical steps required by some other systems, such as turbines. Their compact size offers greater design flexibility for various applications.

Disadvantages of Thermoelectric Generators

Thermoelectric generators don’t convert heat to electricity as efficiently as some other energy technologies. This means they generate less electricity from the same amount of heat. When used for waste heat recovery, where the heat is free, efficiency becomes less of an issue. Thermoelectric generators often cost more per watt of power output at first compared to other technologies.

However, their total cost over a long lifespan can be lower. The initial cost, spread over their long life, makes thermoelectric generators cost-effective in some cases. They also require no maintenance, which reduces lifetime costs.

While there is a lot of knowledge on how to make thermoelectric generator modules, fewer experts know how to design and apply them effectively. This limited expertise makes it harder for thermoelectric generators to become more popular since poorly designed applications can increase costs and lower efficiency.

Despite these drawbacks, thermoelectric generators remain popular because they offer advantages that other energy conversion technologies do not.

Applications of Thermoelectric Generators

Thermoelectric generators have many uses, and we can categorize them by the type of heat source they use to produce electricity.

Common Heat Sources for Thermoelectric Generators:

- Radioactive Decay: Plutonium-238

- Waste Heat: Sources like car exhaust, steel foundries, wood stoves, gas flares, candles, and hot water pipes

- Solar Photovoltaic Panels

- Electronics

- Body Heat

- Renewable Sources: Geothermal and solar thermal

- Combustion: Any fuel source, including internal and external combustion

Thermoelectric Generator Market Report

Thermoelectric generator (TEG) technology has been used in military and aerospace fields for many years. Now, researchers are creating new thermoelectric materials and systems to generate power from both low and high-temperature waste heat. This development presents a great opportunity for the future. These systems can also be made in various sizes and have lower operating and maintenance costs.

The global market for thermoelectric generators was about $320 million in 2015 and reached around $472 million in 2021. It could grow to $1.44 billion by 2030, with an average annual growth rate of 11.8%. Currently, North America holds 66% of the market share and will likely remain the largest market in the near future. However, Asia-Pacific and European countries are expected to grow at faster rates. A study found that the Asia-Pacific market would grow at a compound annual growth rate (CAGR) of 18.3% from 2015 to 2020. This growth is driven by the high demand for thermoelectric generators in the automotive industry, which aims to improve fuel efficiency, along with increasing industrialization in the region.

Researchers are also exploring small-scale thermoelectric generators for wearable technology. These devices aim to reduce or replace charging and extend battery life. Recent studies focused on a flexible thermoelectric material made from silver selenide on a nylon base. Thermoelectric devices can work well with wearables by harvesting energy directly from the human body, creating self-powered devices. One project used n-type silver selenide on a nylon membrane. Silver selenide is a semiconductor with high electrical conductivity and low thermal conductivity, making it ideal for thermoelectric use.

The low-power TEG market, also known as the “sub-watt” market (generating up to 1 watt peak), is growing as it uses the latest technologies. Main applications include sensors, low-power devices, and Internet of Things (IoT) applications. A market research company reported that 100,000 units shipped in 2014 and expects this number to reach 9 million units per year by 2020.

Conclusion

In conclusion, thermoelectric generators (TEGs) play a vital role in converting heat into electricity efficiently. Their solid-state design, reliability, and quiet operation make them suitable for various applications, from space missions to wearable technology. While they may not be the most efficient or cost-effective option initially, their long lifespan and low maintenance needs can lead to overall savings. As research continues to improve materials and applications, TEGs will likely see expanded use in both consumer and industrial markets, contributing to a more sustainable energy future.

FAQs

How much electricity can a thermoelectric generator produce?

A single thermoelectric generator (TEG) can produce between 1 and 125 watts of power. If you connect multiple TEGs together, they can generate up to 5 kilowatts of power, especially when the temperature difference (ΔT) is over 70°C. You can use a heat pipe system as a heat source, which works well with TEGs in systems that recover waste heat.

How is thermoelectric energy produced?

Thermoelectric materials create energy directly from heat by changing temperature differences into electric voltage. For these materials to work well, they need to have high electrical conductivity (σ) and low thermal conductivity (κ).

How does a thermionic generator work?

A thermionic generator uses fission energy to heat a filament in a vacuum. This heat causes electrons to escape from the filament. The electrons then move to a colder electrode, where they get collected and provide electrical current to a device.

What are the advantages and disadvantages of thermoelectric generators?

TEGs have the advantage of being environmentally friendly since they do not create noise pollution. However, they have some disadvantages, including low energy conversion efficiency and the need for a steady heat source.

Read More – Variable Frequency Drive: Types, Benefits, Working Principle