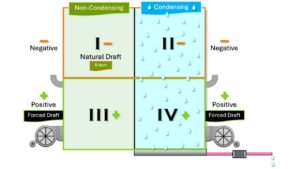

Those who have certified boilers all experience the same testing to examine their venting. Experts categorize vent systems as either being operated with pressure moving in or out of the building. Wastes are also organized by their likelihood to turn the produced gasses into water. Efficient operation in a boiler causes its flue gases to be less hot. Condensation becomes more likely when the air around us is cooler.

Boiler Flue Vent Chart

Category I Vents

Most vent seals are considered Category I vents. Many of them often install Type B vent materials. These work on non-condensing heating systems and function under draft. Because the hot combustion gases are above their dew point, they don’t turn into water.

Type B Vents

Type B vents should be installed for fixtures that do not condense. All of these devices emit flue gases that reach a temperature of 400°F or lower. Natural draft pulls the gases out of the vents and they work because the system is under a vacuum. You generally see them found connected to gas appliances with draft hoods.

Category II Vents

Negative pressures are used with Category II vents as they are with Category I vents. Even so, the flue gases exiting Category II vents are considered cooler than those from Category I. At the lower temperature in the atmosphere, it’s simple for these gases to create condensation. That’s why you see Category II vents in the top section of the chart which reflects their relationship to condensation events. Because of the moisture, the flue needs to contain materials that won’t get corroded.

Category III Vents

Category III vent systems force gases to be removed by a power exhauster running on positive pressure. If there are leaks in the venting system, this pressure may result in trouble. If there’s a problem, poisonous gases such as carbon monoxide might find their way into the house.

Gases are removed from a building using positive pressure in vents, while negative pressure vents depend on natural ventilation. Poorly sealed or unattended vents will make the pressure unit more at risk of leaks.

Since Category III venting systems deal with high flue gas temperatures, fluids do not condense. For this reason, these heat pumps do not condense their output.

Changing your boiler from non-condensing to condensing means checking your flue system carefully before replacing it. Because condensing boilers take more warmth from the exhaust, they operate differently. As a consequence, the gases get colder and sometimes become water before escaping the vent.

Category IV Vents

Cooling for Category IV vents is accomplished with a system that uses positive pressure forced air. Because flue gas in this system may cool under the dew point, these vents are designed to condense. Gas with moisture requires that vent materials not rust.

Direct Venting

With direct venting, the system design has it take air from the outdoor environment, vent out the exhaust gases and completely seal everything in between. Using this arrangement enhances both the safety of the system and its energy performance. Usually, it’s built with two sections: one for getting air in and the other for getting exhaust out.

Direct vent systems don’t run on air inside the home, so your air stays cleaner. They help to reduce the odds of deadly carbon monoxide entering the home. You don’t have to be concerned about exhaust fumes being pulled back inside the house.

There are more ways you can install direct vent systems since they can choose from horizontal or vertical vent setups. Because they’re flexible, they suit many styles of homes and buildings.

Direct vent systems use outdoor air which prevents drafts in your house and helps keep the air inside healthy. Since less is visible from the outside, they look better and make less noise.

Flue Material

In systems from Category One, standard non-condensing boilers normally have double-wall B vent pipes. The double walls allow the flue gases to reach a temperature high enough so condensation does not occur.

Since acidic moisture is produced inside condensing boilers, the flue has to be built from suitable materials. Your materials can include PVC, CPVC, polypropylene or stainless steel. Be sure to consult the boiler manufacturer’s guide before choosing your material.

Switching your boiler to a condensing type means the old metal flues should not be used again. An unprotected condensing boiler may be damaged by the acidic condensate it produces.

The more efficiently condensing boilers operate and the cooler their exhaust gases which helps them require smaller flue pipes. Sometimes, making the flue smaller will help with the draft inside the chimney.

In addition, these kinds of boilers create a large amount of liquid condensate. You should make sure to drill the water away safely. Because condensate is acidic, you might have to see that it is neutralized before it goes into the plumbing system. As a result, pipes are preserved and the environment is shielded.

Conclusion

You have to make sure the flue system is in good shape when you upsize a boiler from non-condensing to condensing. Depending on your new boiler, you may have to alter the pipework. Choose the proper tools, flue diameter and installation, handle the condensate safely throughout the system, obey all safety regulations and insulate and seal the flue when needed.

Read More – How a Condensing Boiler Works