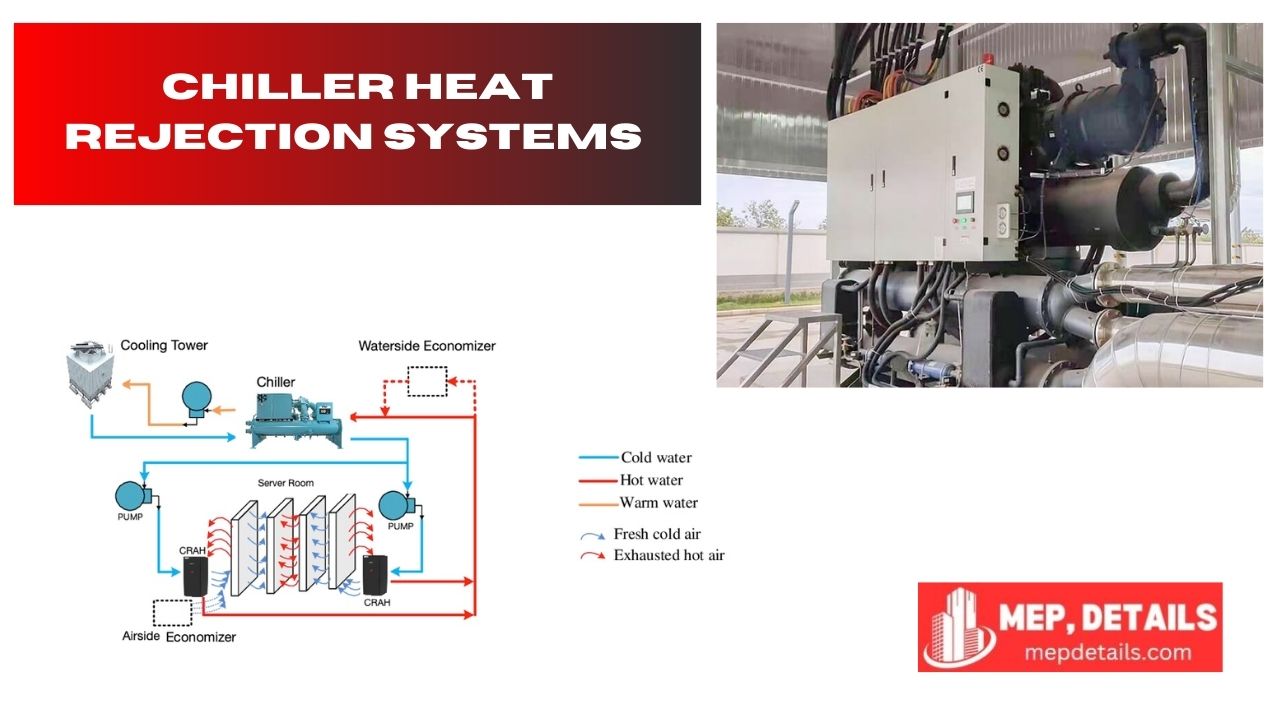

A chiller heat rejection system removes unwanted heat from buildings by transferring it outside. This helps keep indoor spaces cool and comfortable. Properly designed systems save energy, reduce costs, and ensure efficient operation for large cooling needs.

Ever wondered how big buildings stay cool? A chiller heat rejection system does the hard work, pushing unwanted heat outside to keep rooms comfortable. It’s a quiet, smart solution that saves energy and keeps everyone feeling good indoors.

Stay with us as we dive into the world of chiller heat rejection systems. Learn how these systems keep buildings cool, save energy, and make indoor spaces comfortable. Discover why they’re essential for efficient, modern cooling solutions.

How Chiller Heat Rejection Works

Heat rejection is a critical process in the function of chillers in large building applications. It operates in a way that it uses the external environment to expel heat that has been collected from indoor premises, thus maintaining interiors’ temperatures low. When a chiller cools the water or air inside, it means the heat collected has to move to somewhere else. In the heat rejection process, this heat is discharged outside, usually through cooling tower, air cooled condenser and evaporative condenser. It helps not only cool the space but also increases the operation of the cooling system throughout the process.

Learning the fundamental process of chiller heat rejection enables facility managers to create comfortable spaces using less energy. When the system is doing a good job then it cools and provides the best climate to operate in. Heat rejection determines the performance of the chiller together with energy consumption and withstand harsh conditions. It is therefore important to keep these systems well maintained and designed to get the best cooling system all through the year.

Types of Heat Rejection Systems in Chillers

Air-Cooled Heat Rejection

Air-cooled systems use fans to blow air across the chiller coils, removing heat from the system. This setup is easy, and practices are employed in regions where there is insignificant access to water or where moisture content is low. While called water-cooled system, air-cooled systems only use air and do not consume water hence are recommended for an environment friendly option. But they could use more electricity than water-cooled systems because the fan that circulates the coils needs power to churn.

Air-cooled heat rejection systems do not require a lot of space and also can be easily installed and utilized which makes them ideal for little structures or establishments. They are most suitable for middle continental climates where the operation of open ventilation is not accompanied by high temperatures. However, they may perform poorly in an extremely hot environment since the cooling ability of the refrigeration system is diminished by high ambient temperature.

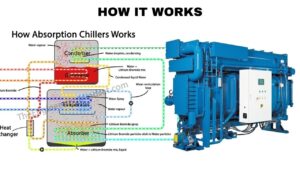

Water-Cooled Heat Rejection

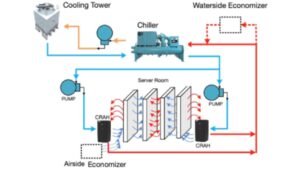

The water-cooled heat treatment system is generally more useful than the cold-air wet system. This makes use of cooling towers whereby heat from the chiller water is transferred to the open air. This means of cooling has more cooling potential and is common in large structures with high cooling requirements. The water in these systems absorbs heat from the chiller and then goes through the cooling tower, where it releases heat into the air through evaporation.

Water-cooled systems are preferred in areas with stable water supplies and high cooling needs. Although they require more maintenance and water treatment, they offer superior efficiency. Additionally, these systems operate well even in hot climates, making them ideal for urban environments where large-scale cooling is essential.

Importance of Heat Rejection Efficiency

The effective heat rejection is critical to the optimal consumption of energy used in cooling appliances. When a chiller heat rejection system functions optimally, a lot of energy is conserved, and costs are cut down. As with any facility, efficiency means a decrease in the load on the chiller, which saves money on the bills and increases the equipment’s lifespan.

Another accurate heat rejection process enhances the pleasantness of the inside climate without constraining the cooler unit. This helps to reduce the rate of repairs and replacements needed often where time and therefore money is saved. These facility teams are encouraged to put more resources into energy efficient parts and habitual preservation to maintain such efficiency throughout the sequential durations.

Components of a Chiller Heat Rejection System

Cooling Towers

Cooling towers are big constructions for removing heat from water cooled chillers. They function by permitting the water being circulated to evaporate and hence cool before it is circulated to the chiller. When water is cooled it is capable of holding more heat in other words it lowers the temperature of the chiller. This is true since cooling towers are good for large loads of heat since they are employed in large commercial facilities with high cooling demands.

The efficiencies of the cooling towers depend on aspects of water quality, temperature, and periodicity of cleaning. Under proper care, the cooling towers can reduce energy uses, hence making them quite efficient for green building operations. They require water treatment to prevent issues like scaling and corrosion, ensuring they run smoothly and last longer.

Heat Exchangers

Hemtal heat exchangers are crucial in the heat rejection cycle by using two fluids to transfer heat. Chambers are typically incorporated in both air-cooled and water-cooled designs, in the improvement of further heat rejection. Heat exchangers enhance the efficiency of the heat transfer enhancing the operation of the chiller system since it shall be working harder.

Designed properly, heat exchangers may significantly help as to the expenses on energy and enhance the work of the cooling circuit in general. Performance is relatively inclined to aspects of design, material construction and frequency of maintenance. When maintained effectively heat exchangers support effective heat rejection systems necessary for cooling buildings in a manner that is energy efficient.

Benefits of a Properly Maintained Heat Rejection System

A critical benefit of a proficient intensity dismissal framework is lower energy costs. Numerous chiller issues happen when parts are not as expected kept up with, prompting workaholic behavior of the framework. This outcomes in higher power costs. Standard support of all parts evades such issues and diminishes costs. The various planned and scheduled visits and checkups can be used to notice and solve any smaller problems before they complicate and become more expensive.

The last benefit is that equipment now has a longer lifespan than it used to be. Maintaining and optimizing the heat rejection system of a chiller also has less of the stress level that causes degradation of the equipment. This means the system will take longer than that needed in replacing these part for some usual breaking downs.By investing in proper maintenance, facilities save on long-term expenses and enjoy reliable cooling year-round.

Environmental Impact of Heat Rejection Systems

The environmental effects of chiller heat rejection systems particularly the water cooled models can be substantial more so if not well controlled. Some systems will require more water and water may be scarce in regions that have poor rainfall. The greatest care should be taken to measure the usage of water and if possible to apply water-conserving techniques to avoid exertion of further pressure on the environment.

In addition, heat rejection systems are other mechanisms that can decrease greenhouse gas emissions because of saving energy. While making choices on which products to use and services to provide maintenance work, the goal is reducing the buildings’ impact on the environment. Such measures including variable speed fan drive or water use reduction cooling tower, enhances green investments enhance sustainability efforts.

Common Challenges in Chiller Heat Rejection Systems

Scaling and Corrosion

Water cooled systems, one of the major difficulties are scales which are formed through deposition of mineral substances in the water. In detail, scaling weakens the system’s heat transfer efficiency and makes the components less efficient in the long run. Another problem that may lead to leaks and system components failure is corrosion. Each of the two can raise maintenance requirements and decrease the efficiency of the system involved.

Getting rid of these waters can cause scaling and corrosion in the chiller heat rejection systems making water treatment important. It is getting common for the facility managers to ensure that the water is treated with addition of chemicals or by adopting filtration to ensure the system’s component is protected as it achieves its heat rejection performance. Such precautions are useful and cost effective ways of avoiding some problems that would otherwise be incurred in future.

High Energy Consumption

Another challenge is the high energy consumption often associated with heat rejection systems. Air-cooled systems, in particular, require constant fan operation, which increases electricity usage. To address this, many facilities are turning to energy-efficient technologies, such as variable-speed drives that adjust fan speeds based on cooling demands.

Reducing energy consumption is critical for cost savings and environmental sustainability. By using advanced controls and regular maintenance, facility managers can keep energy use under control. This results in a system that performs efficiently without causing an unnecessary increase in operational costs.

Best Practices for Efficient Chiller Heat Rejection

One of the best practices for efficient heat rejection is ensuring that the system’s components are properly matched to the chiller’s requirements. When components like cooling towers, heat exchangers, and pumps are sized correctly, the system can operate efficiently without wasting energy. Oversized or undersized parts can lead to unnecessary power use and reduced performance.

Another effective practice is routine maintenance, including cleaning and inspecting the cooling towers, heat exchangers, and water treatment systems. By removing dirt and scaling deposits, facility teams can ensure smooth operation and prevent any unexpected issues. Staying proactive about maintenance is key to keeping the heat rejection system running efficiently over the long term.

Innovations in Chiller Heat Rejection Systems

Owing to the increasing concerns for energy, improvements in heat rejection systems are making chillers more efficient. One late alteration is the establishment of Variable Recurrence Drives (VFDs) on cooling tower fans. VFDs permit fans to change their speed in light of genuine cooling needs, rather than running at high velocities continually. This lessens functional expenses and increments proficiency. Moreover, it upholds harmless to the ecosystem building rehearses. The innovation keeps up with ideal cooling execution while bringing down energy utilization.

One of them is that different approaches to cooling, air based and water based, are combined in an innovative way. Hybrid systems switch between the two methods based on external conditions, providing effective heat rejection while minimizing resource use. Such advancements help buildings stay cool with minimal environmental impact, creating a balance between comfort and sustainability.

Future Trends in Chiller Heat Rejection

The direction for chiller heat rejection is a smarter technique, and the automation controlling system. installation of sensors and Internet of Things devices enables the facility manager to observe system operations in ‘real-time’ and determine which require tuning. Other operational controls involve fans, water usage, and temperature, all of which are fixed and brought to real requirements for efficiency in power consumption.

Manageable materials and green refrigerants are getting some forward movement as guidelines on fossil fuel byproducts and asset utilization become stricter. These patterns highlight critical progressions in energy-saving and harmless to the ecosystem answers for chiller heat dismissal frameworks. Before very long, such advancements are supposed to prompt the improvement of more powerful and eco-cognizant cooling frameworks. The rising spotlight on manageability guarantees a more promising time to come for energy-effective innovations. With these changes, we may before long see cooling frameworks that are superior execution as well as planet-accommodating.

Conclusion

An optimized chiller heat rejection system plays a quintessential role in cooling, energy conservation, and reliability in large buildings. There are also chances of scaling and corrosion at cooling tower heat exchangers especially at water treatment systems hence with proper management of the systems facility managers can cut down on maintenance costs relating to these components as they promote long equipment life. It also implies reduced energy costs and consequently, a more favorable climate inside the building.

Expected developments of smart control systems, and hybrid cooling choices present the peoples prospect of even more efficient chiller heat rejection systems. This being so, these systems cannot compromise environment standards since they incorporate sustainable technologies and management to deal with high cooling requirements. The decision to invest in a good, efficient system has a positive double impact on the functionality of the facility and the impact it has on the environment. It is a smart choice for modern buildings.

FAQs

What is a heat rejection system?

A heat rejection system removes excess heat from equipment or spaces, typically transferring it to the outside environment to maintain cooling.

Where is heat rejected in a refrigeration system?

In a refrigeration system, heat is rejected through components like condensers or cooling towers, which release it outside.

What is the heat rejection factor of a cooling tower?

The heat rejection factor measures the ratio of heat removed by the cooling tower to the chiller’s cooling load, typically slightly above 1 due to inefficiencies.

Why is heat rejection necessary?

Heat rejection prevents overheating, ensuring efficient system performance and extending equipment lifespan.

What is an example of heat rejection?

An air conditioner expelling hot air outside through a condenser is a common example of heat rejection.

Also Read It : Hydropower Plants: Definition, Working Principle, Types