Introduction to 3 Phase Motors

Three-Phase Motors Connect Star and Delta The efficiency and dependability of star and delta connections make them popular in a wide range of commercial and industrial applications. Unlike single-phase motors, these motors run on three phases of power, allowing for smoother, more continuous rotation.

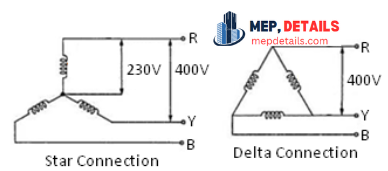

Basics of Star Connection

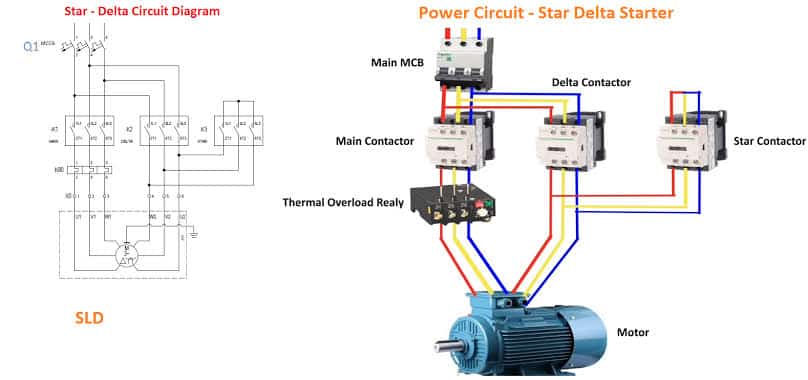

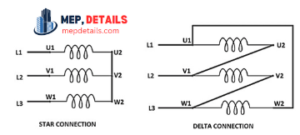

The motor windings’ three phases are joined to a single point to make a star-shaped connection known as a star connection. A Y connection is another name for this arrangement. One end of the supply voltage is connected to each phase, while the other ends are connected to form the star point.

Basics of Delta Connection

The triangular form of the windings in a delta connection is similar to the Greek letter delta. A closed loop is formed by connecting every phase to every other phase. Every phase of the motor receives an application of the supplied voltage.

What is the formula for a three-phase motor’s star connection

Three-phase power, voltage, and current values for the Star Connection (Y)

VL = √3 VPH (or) VL = √3 EPH

What is the differences between Star & Delta connections

| Aspect | Star Connection | Delta Connection |

|---|---|---|

| Configuration | Forms a star or Y shape | Forms a triangular or delta shape |

| Neutral Wire | Requires a neutral wire | Does not require a neutral wire |

| Voltage Distribution | Provides better line voltage balance | May result in unbalanced voltages across phases |

| Load Handling | Suitable for balanced loads | Handles unbalanced loads effectively |

| Starting Current | Lower starting current compared to delta connection | Higher starting current may be required |

| Power Distribution | Balanced power distribution | May experience power imbalance in certain scenarios |

| Applications | Fans, pumps, compressors, where balanced loads are crucial | Conveyor belts, elevators, high-power machinery |

| Efficiency | Efficient for balanced loads | Efficient for handling unbalanced loads |

| Flexibility | Limited flexibility in handling unbalanced loads | More flexibility in adapting to load variations |

| Cost and Size | Generally smaller and less expensive | Slightly larger and may require more wiring |

| Motor Performance | Smooth operation with reduced voltage drops | High-power handling with potential voltage imbalances |

Advantages and Disadvantages of Star Connection

Better line voltage is provided by a star connection than by a delta connection, which results in balanced loads and less voltage losses. But it need a neutral line, which complicates the wiring arrangement.

Advantages and Disadvantages of Delta Connection

The wiring arrangement is made simpler with a delta connection as it doesn’t need a neutral wire. Although it is capable of efficiently handling higher power loads, it may lead to uneven voltages between the phases.

Working Principle of 3 Phase Motor in Star Connection

A magnetic field is produced in a star-connected motor when current passes through the windings and each phase receives the line voltage. Rotational motion is produced by the stator and magnetic field interacting.

Working Principle of 3 Phase Motor in Delta Connection

Phase-to-phase voltage in a delta-connected motor is used to create magnetic fields in the windings. Mechanical work is made possible by the torque that results from this, which rotates the motor.

Comparison between Star and Delta Connection

| Aspect | Star Connection | Delta Connection |

|---|---|---|

| Configuration | Forms a star or Y shape | Forms a triangular or delta shape |

| Wiring Complexity | Requires a neutral wire | Does not require a neutral wire |

| Voltage Distribution | Provides better line voltage balance | May result in unbalanced voltages across phases |

| Load Handling | Suitable for balanced loads | Handles unbalanced loads effectively |

| Starting Current | Lower starting current compared to delta connection | Higher starting current may be required |

| Power Distribution | Balanced power distribution | May experience power imbalance in certain scenarios |

| Applications | Fans, pumps, compressors, where balanced loads are crucial | Conveyor belts, elevators, high-power machinery |

| Efficiency | Efficient for balanced loads | Efficient for handling unbalanced loads |

| Flexibility | Limited flexibility in handling unbalanced loads | More flexibility in adapting to load variations |

| Cost and Size | Generally smaller and less expensive | Slightly larger and may require more wiring |

| Motor Performance | Smooth operation with reduced voltage drops | High-power handling with potential voltage imbalances |

Applications of Star & Delta Connection

| Application | Star Connection | Delta Connection |

|---|---|---|

| Fans | Used in industrial and commercial fans for air circulation and ventilation. | Utilized in fans for various applications requiring high-power handling and speed control. |

| Pumps | Utilized in water pumps for various applications such as irrigation, drainage, and water supply. | Found in pumps for handling high-pressure and heavy-duty pumping tasks in industries. |

| Compressors | Commonly found in air compressors for pneumatic systems, refrigeration, and HVAC units. | Employed in compressors for heavy-duty applications requiring high starting torque and power. |

| Blowers | Employed in blowers for air movement in HVAC systems, industrial processes, and drying applications. | Used in blowers for high-volume air movement and pressure applications in industrial settings. |

| Conveyors | Used in conveyor systems for material handling in industries such as manufacturing and logistics. | Utilized in conveyor belts for high-speed and continuous material transportation tasks. |

| Industrial Mixers | Found in industrial mixers for blending, stirring, and mixing applications in manufacturing processes. | Employed in mixers for efficient mixing and agitation of materials in industrial settings. |

| Centrifugal Separators | Utilized in centrifugal separators for separating liquids and solids in various industrial processes. | Found in separators for high-speed separation and filtration applications. |

| Refrigeration Units | Found in refrigeration units for cooling and preserving perishable goods in commercial and industrial settings. | Used in refrigeration systems for efficient cooling and temperature control. |

| Heat Exchangers | Used in heat exchangers for transferring heat between fluids in HVAC systems and industrial processes. | Employed in heat exchangers for heat transfer in heating and cooling systems. |

| Industrial Ovens and Furnaces | Employed in industrial ovens and furnaces for heating and processing materials in manufacturing. | Found in ovens and furnaces for high-temperature heating and thermal processing tasks. |

| Industrial Dryers | Utilized in industrial dryers for drying materials such as textiles, food products, and chemicals. | Used in dryers for efficient drying of materials in manufacturing and processing industries. |

| HVAC Systems | Found in heating, ventilation, and air conditioning systems for temperature control in buildings and facilities. | Employed in HVAC systems for efficient heating, cooling, and ventilation. |

| Packaging Machinery | Used in packaging machinery for automated packaging processes in manufacturing and logistics. | Utilized in packaging machines for precise control and high-speed operations. |

| Water Treatment Systems | Employed in water treatment systems for pumping and circulating water in filtration and purification processes. | Found in water treatment systems for efficient water movement and treatment. |

| Manufacturing Machinery | Found in various manufacturing machinery for powering equipment such as presses, lathes, and mills. | Utilized in manufacturing machinery for powering heavy-duty equipment and processes. |

Maintenance Tips for 3 Phase Motors

To guarantee the best efficiency and longest lifespan of three-phase motors, regular maintenance is essential. This includes lubricating the motor, checking the windings, bearings, and connections, and keeping an eye on the motor’s performance.

Conclusion

In conclusion, using three-phase motors in a variety of industrial and commercial contexts requires an awareness of the fundamentals and the distinctions between star and delta connections. Improved performance, energy efficiency, and dependability are all benefits of properly choosing, installing, and maintaining these motors.

Unique FAQs about 3 Phase Motors

What is the main difference between a star and delta connection in three-phase motors?

The main difference lies in how the motor windings are configured and how the supply voltage is distributed across the phases.

Can a three-phase motor be converted from star to delta connection and vice versa?

Yes, some motors are designed to allow conversion between star and delta connections, offering flexibility in adapting to different operational requirements.

What are some common applications of star-connected motors?

Star-connected motors are commonly used in applications such as fans, pumps, and compressors where balanced loads and smooth operation are crucial

How does maintenance impact the performance of three-phase motors?

Regular maintenance, including inspection, lubrication, and performance monitoring, is essential to ensure optimal efficiency, longevity, and reliability of three-phase motors.

You may also like – Understanding Indoor Lighting Basics

Hi,

I wanted to see if you’d be interested in a link exchange for mutual SEO benefits. I can link to your site (mepdetails.com) from a few of our high-authority websites. In return, you would link back to our clients’ sites, which cover niches like health, business services, real estate, consumer electronics, and more.

If you’re interested, let me know — I’d be happy to share more details!

Thanks for your time,

Karen

SEO Account Manager

Hi,

Just a quick check, if you can add 3 links to our client sites (in home cleaning, women’s health & co-living sectors) anywhere on your website, we’ll get your business featured on trusted media website – MirrorBrief.com, with a backlink to mepdetails.com, through our journalist partner there. Interested to trade?

Best,

Karen

Collaboration Marketing Manager

Your content always feels purposeful and meaningful to followers

Hi,

Hope all is well.

Long story short… I can link to your site mepdetails.com from 5x legit local business websites (>DR30) — all FOC, no money involved. In return, you’d link to 5 different of my client sites from your end for a mutual SEO boost.

Interested? I can send you the site list to choose.

Cheers,

Karen

Hi,

Hope all is well.

Long story short… I can link to your site mepdetails.com from 5x legit local business websites (>DR30) — all FOC, no money involved. In return, you’d link to 5 different of my client sites from your end for a mutual SEO boost.

Interested? I can send you the site list to choose.

Cheers,

Karen

Hi,

Hope all is well.

Long story short… I can link to your site mepdetails.com from 5x legit local business websites (>DR30) — all FOC, no money involved. In return, you’d link to 5 different of my client sites from your end for a mutual SEO boost.

Interested? I can send you the site list to choose.

Cheers,

Karen