When it comes to types of HVAC insulation and their characteristics, knowing the possibilities allows choosing appropriate material for the house. It is divided into fiberglass, open cell and closed cell spray foam each with its attributes that make it durable in providing comfort and energy efficiency.

Do you find yourself unsure of the various types of HVAC insulation and what makes them different? The selection of an appropriate insulation results in a reasonable difference in the comfort levels of your house and cost of energy. So, let us look at the logical steps to make a workable decision to enable you to come up with the best decision!

Please continue reading with us as we explore the various kinds of HVAC insulation and some of the special attributes of each. Knowledge of these choices and flexibility will enable you to make the right choices for your home’s usefulness and comfort. Let’s explore together!

Understanding HVAC Insulation: Why It’s Important

Insulation plays a crucial role in the heated as well as ventilated as well as air conditioned facilities to counter check either heat gain or heat loss, improve utility of electricity and provide total comfort to the occupants. Insulation in HVAC systems is not only used for basic temperature regulation but also for fighting energy losses, avoiding formation of condensation and noise within ducts. Obviously, if a structure is not insulated correctly, then its heating and air conditioning systems are unable to run effectively, therefore power costs rise as well as the wear and tear experienced by the system also rises.

There are particular types of insulation in that HVAC system for the reason that various types of insulation are aimed at solving various problems in an HVAC system. Each of the insulation types has its properties depending on thermal efficiency or insulation factor, its ability to control moisture, and its ability to last long or not depending on the environment in which it will be used . It is therefore important for one to understand the differences between different insulation materials so as to meet the building’s needs and at the same time optimize the performance of HVAC systems.

Fiberglass Insulation: A Widely Used Option

Fiberglass insulation is widely used for HVAC systems because of the ability to provide good thermal performance and cost efficiency. It is a product formed through the use of fine glass fibers and its R-value meanings reflect its ability to block heat flow and help maintain the indoor temperatures. Fiberglass insulation is available in various forms, including batts, rolls, and loose-fill, making it adaptable for different applications within the HVAC system.

This type of insulation also effectively minimizes condensation, which is essential in preventing moisture-related damage to HVAC components. Additionally, fiberglass is fire-resistant and has sound-absorbing properties, reducing noise transmission through ductwork. However, fiberglass insulation requires proper installation to avoid gaps or compression, as improper installation can decrease its effectiveness and lead to air leaks.

Mineral Wool Insulation

Mineral wool can also be called the rock wool, or stone wool which is produced with the base of volcanic materials or industrial slag enjoying high coefficient or thermal insulation and high durability level. The insulation material also offers high acoustic performance, which is crucial to HVAC systems in different commercial buildings or noisy spaces. Mineral wool offers better fire resistance compared with other types of insulating materials and therefore is well suited to systems where this attribute is essential.

Apart from thermal efficiency, the mineral wool is also moisture resistant, that is does not absorb water hence reduces the incidences of mold and mildew. This characteristic make it suitable for HVAC systems that are exposed to fluctuations in humidity levels. Nevertheless, mineral wool is denser to other varieties of insulating materials and might thus have to be supported during installation, chiefly when dealing with ducts.

Foam Board Insulation: Lightweight and Efficient

Styrofoam insulation boards, that can be made out of polystyrene, polyurethane, or polyisocyanurate, is well appreciated for its light weight and insulation effectiveness. The boards provided a high R-value to thickness ratio so that it can reduce heat flow effectively. Common applications include those situations where requirement of insulation with high performance is required within small cross-sections like in HVAC systems.

Another advantage of foam board insulation is its low permeability, that helps prevent moisture from accumulating and therefore preventing the formation of condensation which is very dangerous for the HVAC system. The features of foam boards giving it a certain degree of stiffness include easy fixing on the duct surfaces; however, special attention needs to be paid to the blank locations as they create gaps that allow air escapes. That is why foam board insulation is comparatively costly to other materials and when it is exposed to high temperatures, it releases gasses, which may be unsuitable in some circumstances

Reflective Insulation: Ideal for Radiant Heat Control

Reflective insulation as its name suggests is specially developed to reflect radiant heat hence it’s widely used in HVAC system in areas that experiences warm climate. This insulation type usually consists of a foam or plastic layer, with a foil layer that reflects heat off the surface. Reflective insulation is effective due to the fact that it minimizes the amount of heat sucked through ducts and this is favorable is areas where cooling is a major function of HVAC.

Reflective insulation has one important shortcoming in cold climates: It does not come close to fiberglass or mineral wool as far as thermal resistance is concerned. However, it is more effective when used in other coordinated types of insulation to offer overall heat management. Thus, reflective insulation is particularly useful in preventing radiant heat while not being as useful in preventing conductive heat transfer – its use should be decided on a case by case basis.

Spray Foam Insulation: Total Encapsulation for productivity

One such type that is used particularly in HVAC applications is the spray foam insulation that comes in the open-cell and closed-cell form. In terms of efficiency, this insulation material cannot be beaten because it seals thoroughly to minimize air leakage. The foam is sprayed directly to the interior of the ducts and instantly expands to fit any gaps that exist, thus air tightness is created. Closed cell spray foam has a greater density and a better thermal value while the open cell type has more elasticity enabling it to accommodate slight movement in ducting.

The closed cell foam covering reduce air leakage mostly contributes to energy conservation and also in controlling moisture problems like condensation within ducts. It is also long lasting as a form of insulation and act as an insulator against sound too. Though it may be costly compared to other forms of insulation, it may also be a bit challenging to install and this has to be done professionally to avoid disasters such as fires.

Polyethylene Insulation

Polyethylene insulation is known for its flexibility and moisture that may be inappropriate for certain HVAC applications. This insulation material is commonly used to wrap pipes and ducts due to its lightweight structure and high adaptability. Polyethylene is naturally resistant to moisture, preventing condensation and reducing the risk of mold growth in HVAC systems exposed to high humidity.

In addition to moisture resistance, polyethylene insulation offers moderate thermal insulation. However, its R-value is lower than that of fiberglass or foam board insulation, which may limit its effectiveness in environments with extreme temperatures. Polyethylene is often chosen for its flexibility and ease of installation rather than high thermal resistance.

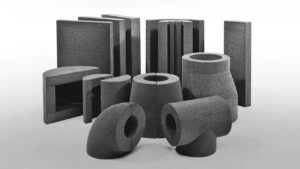

Cellular Glass Insulation: Robust and Fire-Resistant

Cellular glass insulation is composed of crushed glass and provides high durability along with excellent fire and moisture resistance. This material is non-combustible and retains its structural integrity under high temperatures, making it a reliable choice for HVAC systems where fire safety is paramount. The closed-cell structure of cellular glass prevents moisture absorption, which protects the HVAC components from rust and corrosion.

Though cellular glass insulation offers solid thermal performance, it is heavier and can be more expensive than other types of insulation. Its installation requires precision, as cellular glass is rigid and not as flexible as other materials. Despite these limitations, its durability and fire-resistant properties make it an optimal choice for industrial HVAC applications.

Elastomeric Foam Insulation: Flexible with Closed-Cell Structure

Elastomeric foam insulation is known for its flexibility and closed-cell structure, which provides effective moisture resistance. It’s widely used in HVAC systems where condensation control is necessary, as the closed-cell design prevents water absorption. Elastomeric foam’s flexibility makes it easy to install on complex duct shapes and reduces the chances of air leaks.

The thermal insulation properties of elastomeric foam are suitable for both hot and cold applications, providing versatility across different HVAC systems. However, it may not offer as high an R-value as materials like fiberglass or mineral wool, so it’s often used in combination with other types of insulation. Elastomeric foam is durable and resistant to mold growth, making it a popular choice in humid environments.

Click on it:https://mepdetails.com/how-to-read-pump-curves/

FAQs

What are the different types of insulation in HVAC?

The main types of HVAC insulation include fiberglass, mineral wool, foam board, reflective, spray foam, polyethylene, cellular glass, and elastomeric foam, each offering unique thermal and moisture resistance properties.

What are different types of insulation?

Common insulation types are fiberglass, mineral wool, foam board, reflective, cellulose, spray foam, and radiant barriers, chosen based on their thermal efficiency and application needs.

How many types of HVAC are there?

The primary types of HVAC systems are split systems, hybrid systems, ductless systems, and packaged systems, each catering to different heating and cooling requirements.

Which among the characteristics should an insulation have?

Effective insulation should have high thermal resistance, moisture resistance, durability, and sometimes soundproofing and fire resistance, depending on the application.

What are the 4 classes of insulation?

The four insulation classes are Class A, B, F, and H, each with a maximum temperature limit suitable for different HVAC and electrical applications.

Conclusion

From the knowledge of the types of HVAC insulation and the characteristics that have been explained it is clearly important to understand the kind of insulation that best fits any building in order to achieve an optimum energy efficiency and the comfort within the building. Every type of insulation, from fiberglass up to the spray foam, has its properties suited for a certain application, and it is indispensable to select the proper material for the HVAC system.

Choosing the right type of insulation will improve your system’s efficiency, save energy, and protect against moisture damage. As you decide what type of HVAC insulation you use and what type of insulation it has, understand that only choosing the right style for your HVAC system will give your systems the life and durability which it deserves.

Nice work

@Rehan Thanks