A Variable Frequency Drive (VFD), also known as an adjustable-speed or AC drive, controls the speed and torque of an AC motor by changing the input frequency. It also manages voltage or current variations, depending on its design. VFDs can be found in various devices, from small appliances to large compressors, improving energy efficiency compared to hydraulic systems. Since the 1980s, advancements in power electronics have made VFDs smaller, cheaper, and more efficient. This article explains what a VFD is, how it works, its types, applications, benefits, and drawbacks.

What is a Variable Frequency Drive?

A Variable Frequency Drive (VFD) controls an electric motor by changing the frequency and voltage of its power supply. It can also manage how quickly a motor starts or stops. While the VFD adjusts the frequency and voltage, we usually call this “speed control” because it affects how fast the motor runs.

There are many reasons to control motor speed, such as:

- Saving energy and improving efficiency

- Converting power in hybrid systems

- Matching the motor’s speed to the task

- Adjusting the motor’s torque or power to the process

- Creating a better work environment

- Lowering noise levels from fans and pumps

- Reducing stress on machines, which helps them last longer

Lowering peak power use to avoid high demand prices and allowing smaller motors

Modern VFDs also offer networking and diagnostic features that help improve control and boost productivity. Because of energy savings, better motor control, and reduced peak current, a VFD is a good choice for many motor-driven systems.

VFDs are most commonly used to control fans, pumps, and compressors, which make up 75% of all drives in use worldwide.

Other motor controllers include soft starters and across-the-line contactors. A soft starter is a solid-state device that smoothly brings a motor to full speed during startup. An across-the-line contactor applies full voltage to the motor right away.

How Does a Variable Frequency Drive Work?

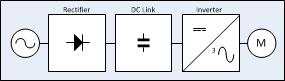

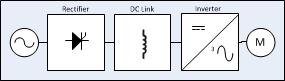

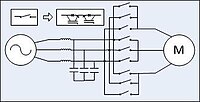

A Variable Frequency Drive (VFD) controls AC motors. It takes in AC power, reduces the input voltage, and converts it into DC voltage. After that, the VFD changes the DC voltage back into AC with an adjustable frequency that matches the motor’s speed. By adjusting the output frequency, the VFD controls the motor’s speed. It can create up to 1000 pulses per revolution of the motor’s rotor, ensuring smoother speed control than other methods like V/F control. Unlike V/F control, VFDs can bypass the V/F converter to protect motors from overload.

Types of Variable Frequency Drive (VFD)

AC drives can be grouped into the following common types:

- Voltage-Source Inverter (VSI) Drives: In VSI drives, the DC output from the diode-bridge converter stores energy in a capacitor. This supplies a steady voltage input to the inverter. Most drives use the VSI type with a PWM (pulse-width modulation) voltage output.

- Current-Source Inverter (CSI) Drives: In CSI drives, the DC output from the SCR-bridge converter stores energy using a series-inductor connection. This supplies a steady current input to the inverter. CSI drives can use either PWM or a six-step waveform output.

- Six-Step Inverter Drives: These are now mostly outdated. Six-step drives can be either VSI or CSI types. They are also called variable-voltage inverter drives, pulse-amplitude modulation (PAM) drives, square-wave drives, or DC chopper inverter drives. In a six-step drive, the DC output from the SCR-bridge converter is smoothed using a capacitor and series-reactor connection. This supplies a quasi-sinusoidal, six-step voltage or current input to an induction motor.

- Load Commutated Inverter (LCI) Drives: LCI drives are a special type of CSI. In these drives, the DC output from the SCR-bridge converter stores energy through a DC link inductor. This supplies a quasi-sinusoidal six-step current output from a second SCR-bridge inverter to a synchronous machine. Low-cost LCI drives using SCR-thyristors are common in high-power, low-dynamic-performance applications like fans, pumps, and compressors, with ratings up to 100 MW.

- Cycloconverter or Matrix Converter (MC) Drives: Cycloconverters and matrix converters are AC-to-AC converters without an intermediate DC link for energy storage. Cycloconverters act as a three-phase current source using three anti-parallel-connected SCR-bridges in a six-pulse setup. Each phase converts fixed line-frequency AC voltage into a variable load frequency. MC drives are based on IGBTs.

- Doubly-Fed Slip Recovery Systems: This system feeds rectified slip power to a smoothing reactor, which supplies power back to the AC supply through an inverter. The motor speed is controlled by adjusting the DC current.

Applications of VFDs

VFDs (Variable Frequency Drives) have many applications in electrical and motor-controlled systems. They help regulate power to save energy when full power isn’t needed.

Swimming pool filtration systems

VFDs are useful in indoor swimming pool filtration systems to improve cleanliness and lower electricity consumption. They adjust the water flow based on need, which can cut energy use by varying water volume. About 40% of a pool’s energy goes into filtering water. A VFD-controlled pump helps recycle water by drawing it into the filtration system.

Pressure booster pumps

Large buildings like hotels need strong water pressure to reach all rooms, including bathrooms and showers. VFDs offer a better solution than pressure control valves. They save more energy and reduce maintenance costs.

HVAC systems

VFDs have been used in HVAC systems for years. While they used to mainly control capacity, today they also balance fans and pumps, monitor equipment, and reduce energy use during peak times. VFDs also reduce wear and tear on HVAC components because they require less energy to start motors, which lowers the stress on parts.

Benefits of Variable Frequency Drive (VFD)

- Energy Savings: Many motor applications that run at a fixed speed using AC power can save energy when operated at variable speeds with a Variable Frequency Drive (VFD). This is especially true for fans and pumps with variable torque, where power usage drops significantly with even a small reduction in speed. For example, when a motor runs at 63% of its full speed, it uses only 25% of its full power. This follows the affinity laws that explain the relationship between speed, torque, and power in centrifugal systems. In the U.S., about 60-65% of electricity goes to powering motors, with 75% of these motors driving variable-torque fans, pumps, and compressors. By using VFDs, up to 18% of the energy consumed by 40 million motors could be saved. However, only about 3% of installed motors currently use VFDs, though around 30-40% of newly installed motors include this technology.

- Control Performance: VFDs help improve control over processes in industrial and commercial settings, influencing factors like speed, pressure, flow, temperature, torque, and tension. Traditional fixed-speed motors start with high torque and can cause current surges up to eight times higher than the full-load current. VFDs, on the other hand, gradually bring motors up to speed, reducing both mechanical and electrical stress. This extends the life of the motor and its components while lowering maintenance and repair costs. VFDs can also run motors in special patterns, like the S-curve pattern, which helps smooth out acceleration and deceleration in applications like conveyors. This reduces mechanical stress and prevents issues like backlash during speed changes.

In some cases, DC drives may be more suitable than AC drives, especially when continuous low-speed operation, frequent acceleration and deceleration, or working in hazardous areas are required.

Disadvantages of Variable Frequency Drive

Here are some disadvantages of using a Variable Frequency Drive (VFD):

- Complexity: Installing and maintaining VFDs can be more complicated compared to other motor control systems.

- Harmonics: VFDs can create electrical harmonics, which may disturb other equipment or power systems.

- Heat: VFDs produce heat, so they may need cooling fans or other cooling systems to manage this heat.

- Interference: VFDs can cause electromagnetic interference (EMI) or radio frequency interference (RFI), which can affect other electronic devices.

- Voltage spikes: VFDs can cause sudden voltage spikes, which may damage the motor or other equipment.

Conclusion

A variable frequency drive (VFD) controls the speed and torque of an AC motor by changing the frequency and voltage of its power supply. It has three key parts: a rectifier, an inverter, and a control system. VFDs are commonly used in industries to manage AC motor speeds in equipment like fans, pumps, and compressors. They enhance efficiency, performance, quality, and safety by allowing smooth speed control. Additionally, VFDs help lower energy use, reduce costs and noise, and minimize environmental impact by adjusting output to meet demand.

FAQs

What is a variable frequency drive?

A variable frequency drive (VFD) controls an electric motor by changing the frequency and voltage of its power supply, managing the motor’s speed during start and stop.

What is the difference between VFD and VSD drive?

A variable frequency drive (VFD) controls AC motors, while a variable speed drive (VSD) can control both AC and DC motors by adjusting frequency or voltage.

What are the advantages of VFD?

VFDs offer benefits like controlling starting current, reducing power disturbances, requiring less power at start, managing speed and acceleration, adjusting torque, and saving energy and costs.

Why does VFD convert AC to DC?

VFDs convert AC to DC to optimize motor control, allowing precise speed adjustments and improving energy efficiency in various industrial applications.

Read More – Secondary Emission Explained