Cold store is technique which is used to by peoples to keep things cool in the food and medicine industry. they makes cold rooms using multiple things one of the most common technique is using freezers , refrigerators and air condition. they Use their cold rooms to keep medicines, foods and other things on the sites like restaurants, warehouses etc. this is very important all over the world and still its very useful.

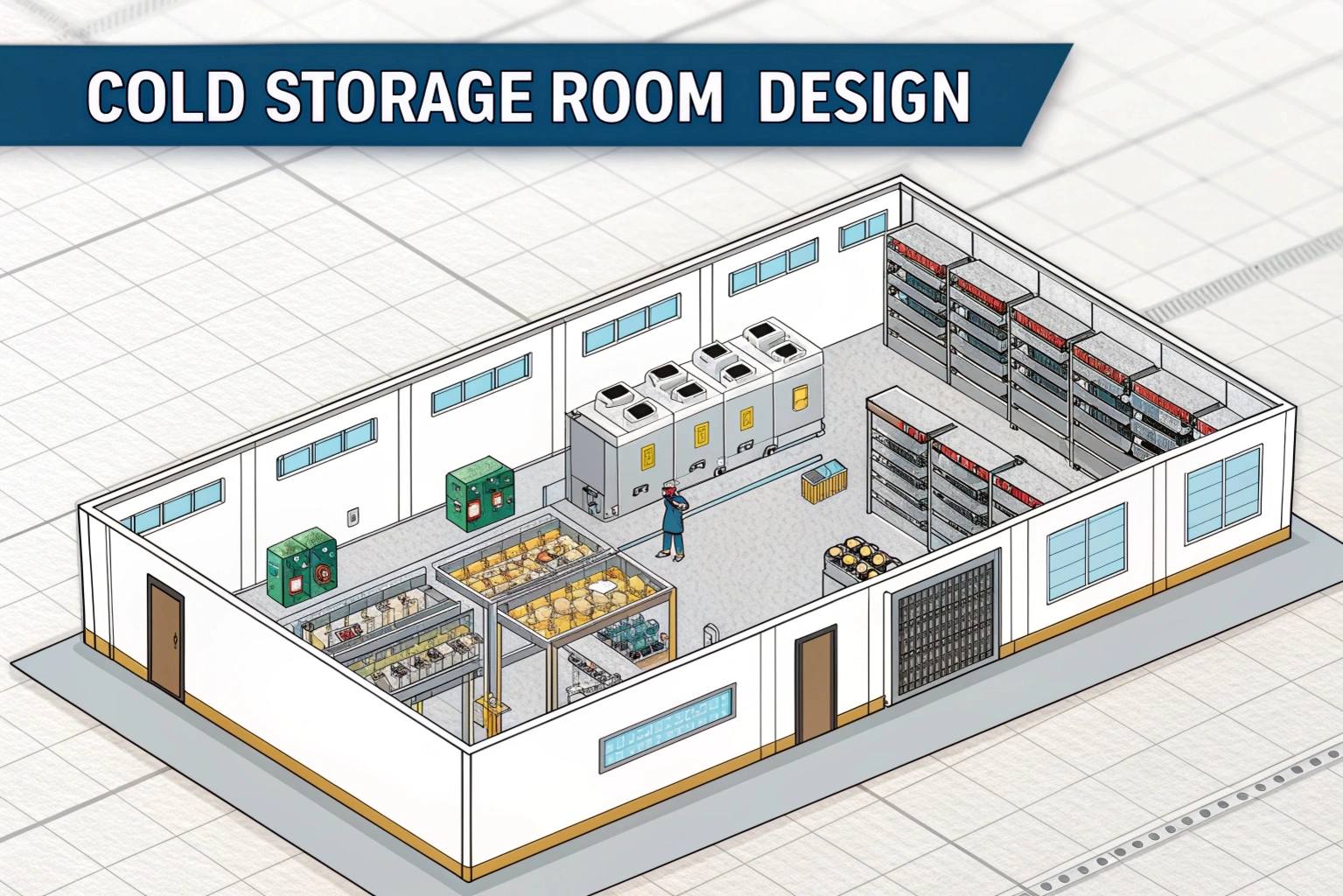

Cold store planning is technique which is used to by engineers to make cold store effective. they obtains good design using multiple parameters one of the most common parameter is insulation , refrigeration systems , and ventilation. they Use their design to make cold store run smoothly on the sites like warehouse, storage etc. this is very important all over the world and still its very difficult.

Cold Store Design Considerations

- Temperature Requirements

The first step in designing a cold store is to define the internal temperature range based on the type of products to be stored. For example:

- Chilled storage: +2°C to +5°C (for fruits, vegetables, dairy)

- Frozen storage: -18°C to -25°C (for meats, seafood, frozen meals)

- Blast freezer: down to -35°C (for rapid freezing of fresh produce)

- Heat Load Calculation

Accurate heat load estimation is critical to determine the size of the refrigeration unit. Factors considered include:

- Internal product load (volume and entry temperature)

- Infiltration through door openings

- Lighting and equipment heat

- People heat gain

- Heat gain through walls, ceiling, and floor

- Insulation and Wall Panels

Insulation is technique which is used to by peoples to reduce heat ingress in cold stores. they obtains good insulation using multiple materials one of the most common technique is polyurethane or polystyrene panels. they Use their R-values to make cold stores more effecient on the sites like warehouses, factories etc. this is very important to minimize refrigeration demand all over the world and still its very necessary. Proper sealing of joints, corners, and door frames is also very important to prevent moisture and air leakage. High-quality insulation reduces heat ingress and minimizes refrigeration demand. Cold stores typically use polyurethane or polystyrene panels with high R-values. Proper sealing of joints, corners, and door frames is essential to prevent moisture and air leakage. - Refrigeration System Selection

Refrigeration system is technique which is used to by peoples to keep things cool, they can be centralized or desentralized its depend on how big is facility, they have many options like

- Air-cooled or water-cooled condensing units

- Refrigerants such as R404a, R134a, or eco-friendly alternatives

- Control systems for defrosting, temperature monitoring, and alarms

- Floor and Drainage Design

Cold store floor is technique which is used to make it strong and it can handle load from rack and forklifts. they uses heated floor slab or vapor barrier to prevent condensation and frost heave and all this things. they make proper drainage so that sanitation is good and microbial growth is less this is very important in cold store. - Lighting and Safety

LED lighting is technique which is used to save energy and make less heat. they includes emergency lighting, anti slip floors and alarms for temp deviation or door opening to make safe and comply with rules. this is very importent for safety and all over the world they use this to save energy and make less heat emission.

Applications of Cold Stores

Cold rooms are used in:

- Food processing units and supermarkets

- Pharmaceutical warehousing

- Floriculture and seed storage

- Logistics and distribution centres

Designing new facility or upgrading old one we need to think about design things so that it work good for long time and we save money also.