Condensing boilers heat water for homes or buildings using gas or oil. The systems heat the water by capturing heat from water vapor in the car’s exhaust. It improves the energy use so heat waste falls to less than 10%. The system removes extra water from the air which is called condensate. In many countries, a condensing boiler is now either necessary or eligible for monetary incentives.

In this guide, we’ll show you exactly how condensing boilers function, where they can be found and why they are more efficient than standard boilers. We’ll assist you in working out which style fits the design of your home or business.

How Standard Boilers Work

Just one heat exchanger is used by a standard non-condensing boiler to move energy from the burning fuel to the water. As soon as cold water reaches the heat exchanger, it receives heat from the fuel that’s being burned by the air. The water overheats and after that, it leaves to keep your home at a comfortable temperature or give it hot water.

The burn processes of fuel release hot flue gases into the unit. The gases leave the boiler via a vent and go into the outdoors. With high temperatures in your home, you waste money on heat you’ve already paid for. If your boiler is 75% efficient, there’s a 25% loss of money you’ll have to cover from flue emissions.

Because condensing boilers catch the heat from flue gases, they tend to work better.

How Condensing Boilers Work

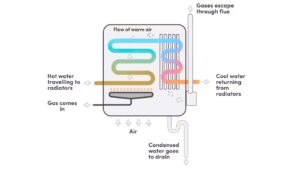

Two heat exchangers in converting boilers are used to cut energy consumption further. Extra heat is taken from the hot gases by a second heat exchanger before they are sent out. They contain moisture inside them. Moisture collects as water when the boiler cools and this water is drained from the same place an air conditioner would let water go.

The water you get called condensate contains acid. Treatment must be done to wastewater before it is allowed into the home’s drainage lines. Put a small filter, stuffed with limestone, over the drain line. It assists in removing acids from your drinking water.

The water that goes into the boiler goes first through the second heat exchanger. It raises the temperature before it gets to the most important heat exchanger. The boiler benefits from the second heat exchanger by allowing it to suck more heat from the flue gas. That’s the main reason condensing boilers are more energy efficient—they recover heat that regular boilers let go.

A condensing boiler can become 90-98% efficient, as opposed to regular boilers which only hit 75-84% efficiency. Being so fuel-efficient reduces waste as well. If you put $1 into regular fuel, you’ll end up losing about a quarter. So, in a 95% condensing boiler, the most you’ll waste is $0.05.

Inside a condensing boiler, hot flue gas is flowing one way, while water goes the other way. The flue gas travels through the main heat exchanger, starting things off and the water moves into the secondary heat exchanger first. Using this arrangement helps put extra heat into the water, so you save energy and money.

Flue Gas Material

Boilers that operate by condensing emissions produce gases that are far cooler than those of regular models. That’s the reason why most manufacturers advise installing PVC or CPVC pipes.

Modern boilers save money and effort because plastic pipes are both cheaper and simpler to install than the metal flues needed for older boilers.

If you like learning the technical side of cooking, here’s something useful: each pound of steam condensation releases about 970 Btu of energy. Because of this extra heat, the boiler does not need to waste as much energy, since a standard boiler just sends it into the air. The best performance from the boiler happens when the return water temperature is low.

If the water isn’t over 130°F (54.4°C), the boiler will create steam and the best return temperature should be near 60°F (15.5°C).

If you’re working with commercial buildings, maintain the supply water temperature at about 140°F. Using tools improves the company’s productivity. The engineer should check if the heat exchangers or other accessories can operate effectively with lower temperatures, since at lower temperatures more coils will be needed.

Things to Know Before Changing from a Non-Condensing Boiler to a Condensing Boiler

Keep these important considerations if you want to replace your commercial non-condensing boiler with a high-efficiency condensing boiler.

- The water in your system should be kept cold. Experts recommend that boiling your water should not reach 130°F (54.4°C). Using low condensate return temperature improves the performance of the condensing boiler.

- Place a suitable drain for condensate in your system. Because condensing boilers give off acidic water, you must have a drainpipe fitted with an inline filter to stop this from happening. It’s important to link the setup to a drain receptor certified by the toilet manufacturer.

- Use PVC or set up the flue pipe with similar material. Because the gases released by condensing boilers are both cooler and more damaging, they need special venting materials.

- Get a heat exchanger that won’t corrode. A stainless steel surface is the best choice because it always lasts longer.

- Check to see what the delta-T is on the refrigerator in your home. Notice how far apart the temperature of the supply and return water is. In early systems, the temperature step may be as little as 10 degrees, but today’s condensing boilers can handle a bigger difference between inlet and outlet water. Due to that, the system needs less water and pressure, helping to cut energy expenses of the pump.

- The flow sensors need to be able to monitor water flow that isn’t as high as standard. You should still get good results even with a bigger range of temperatures and slower moving air.

- Find out the right spots for condensing boilers. These systems do well in residential water heaters, pools, water-source heat pumps, radiant floors, snow melting systems and geothermal systems, since they all use water to cool the space.

Conclusion

Condensing boilers allow you to heat your property more efficiently, while saving both energy and money. They receive their heat from the warm exhaust gases that other boilers would just throw out. As a result, you can save on your gas by helping the vehicle work efficiently. If you set everything up right and maintain your system well, you’ll see less of a carbon footprint and cleaner energy. A lot of people decide to use condensing boilers for their many lasting positive aspects. If it’s important to save energy and have more efficiency, choosing a condensing boiler may be right for you.

FAQs

How does a condensing boiler work?

A condensing boiler uses additional heat from the gases by condensing water vapor. The result is that efficiency is raised by 10–12%.

What are the disadvantages of a condensing boiler?

These types of boilers tend to be expensive at the beginning, require special installation, may freeze when it’s cold and could result in greater maintenance.

At what temperature does a condensing boiler condense?

Condensing starts as soon as the return temperature drops to about 55°C (131°F). Thanks to this, waste gases heat up the boiler once more.

What is the difference between a condensing boiler and a standard boiler?

With condensing boilers, heat from gases is used and put to good use, allowing us to conserve energy. Release of waste heat and gases from standard boilers increases both emissions and the loss of energy.

Read More – How to Size Plumbing Water Pipes Using Fixture Units