Electric automobiles are essential to infinite claims, powering the whole thing from domestic appliances to commercial system. Among numerous kinds, the 3-phase AC induction motor is one of the maximum extensively used because of its performance and reliability. This article explores how these motors occupation, their components, and their import in modern expertise.

What is an Electric Motor?

At its center, an electric powered motor is a tool that converts electric energy into mechanical electricity. This change occurs through electromagnetic interactions between still and rotating workings. Electric motors come in various designs; however, the induction motor stands out for its simplicity and efficiency.

Types of Electric Motors

Electric motors may be categorized into essential types: DC (Direct Current) cars and AC (Alternating Current) cars. While DC vehicles are straightforward in layout and operation, AC cars, specifically induction vehicles, have grow to be the spine of industrial packages.

- DC Motors: Operate on direct current and are commonly used in packages requiring variable speed manipulate.

- AC Motors: Utilize alternating present day and are divided into synchronous and asynchronous vehicles, with induction cars being a subset of the latter.

Understanding three-Phase AC Induction Motors

3-section AC induction motors are a form of AC motor that is predicated on a rotating magnetic field to generate motion. They are characterized by way of their three-phase strength supply, which affords a more consistent and green operation compared to single-section automobiles.

The Basics of three-Phase Power

In a three-segment electricity gadget, 3 alternating currents are generated, each section offset with the aid of 120 stages. This arrangement permits for a non-stop energy supply, making sure smoother operation of the motor. The benefits of a 3-phase system include:

- Higher efficiency

- Reduced size of motor

- Improved torque characteristics

How Does a three-Phase Induction Motor Work?

The process of a three-phase instruction motor is primarily based on the precept of electromagnetic introduction. Here’s a collapse of the technique:

-

Creation of the Rotating Magnetic Field

When a three-segment AC supply is connected to the stator windings of the motor, it generates a rotating magnetic subject. This subject rotates at synchronous velocity, determined by way of the frequency of the AC supply and the range of poles inside the motor.

-

Induction of Current in the Rotor

The rotor, normally made from conductive material, is positioned inside the magnetic area. As the sector rotates, it induces an electromotive pressure (EMF) in the rotor, inflicting it to generate its own magnetic subject. This interplay between the rotor’s magnetic field and the stator’s rotating area creates torque, ensuing in motion.

-

Slip and Motor Speed

The distinction between the synchronous pace of the magnetic subject and the real pace of the rotor is referred to as slip. Slip is essential for the operation of induction cars, because it allows the rotor to expand torque. The quantity of slip varies with load; greater load requires greater slip to hold overall performance.

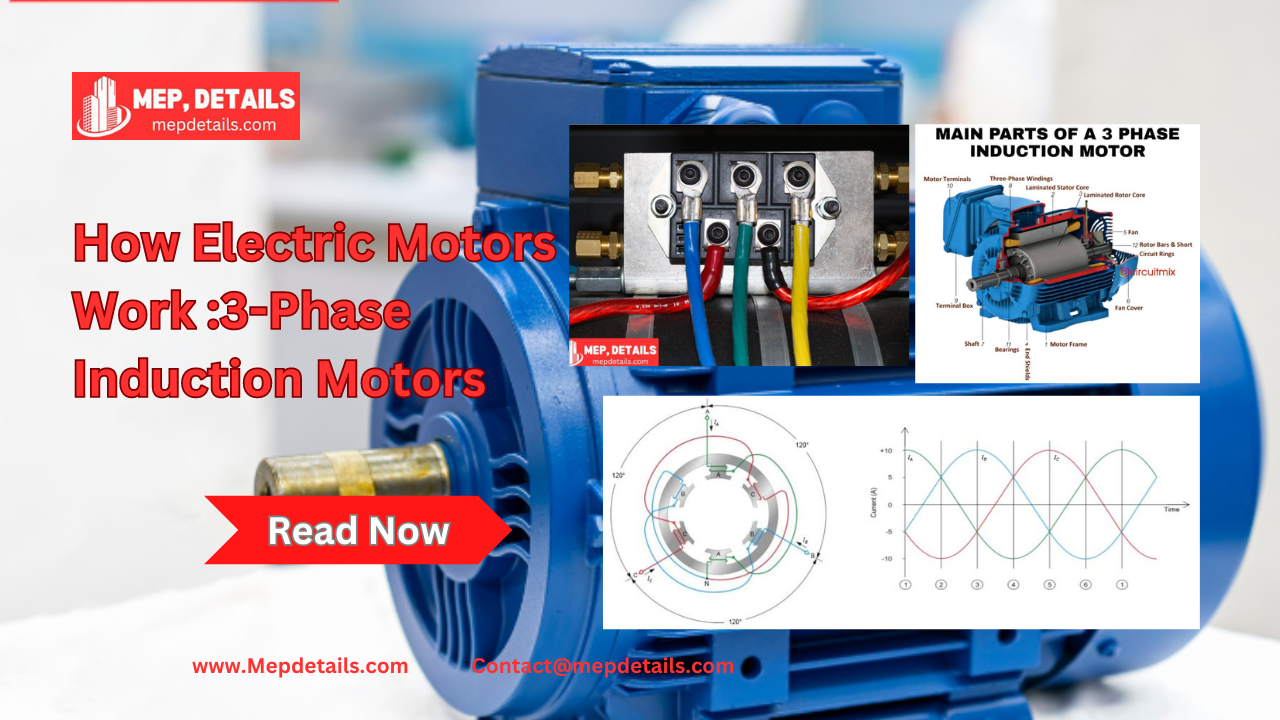

Main Components of a 3-phase AC induction motor

Understanding the number one workings of a three-phase induction motor is crucial for greedy its operation.

-

Stator

The stator is the desk bound a part of the motor, inclusive of windings that create the rotating magnetic area when energized. It is made from laminated iron cores to minimize strength losses because of eddy currents.

-

Rotor

The rotor is the rotating a part of the motor and may be of two sorts: collector cage or wound. The saver crate rotor is greater common due to its easiness and durability.

-

Bearings

Bearings guide the rotor and permit it to rotate freely within the stator. Proper lubrication and protection are vital for his or her toughness.

-

End Shields

End shields residence the bearings and provide structural assist to the motor. They also defend the inner components from dirt and particles.

Wiring Connections in a 3-phase AC induction motor

Correct wiring is important for the ultimate overall performance of a 3-section induction motor. The connections can be configured in two important ways: megastar (Y) and delta (Δ).

Star Connection

In a star connection, one end of each winding is connected to a common point, forming a ‘Y’ shape. This configuration is ideal for starting the motor with a lower voltage, reducing the initial inrush current.

Delta Connection

In a delta connection, every winding is attached cease-to-end, forming a closed loop. This setup permits for better torque and is generally used once the motor is jogging at complete velocity.

Applications of 3-phase AC induction motor

3-segment induction vehicles are utilized in a wide array of applications due to their robustness and performance.. Some common uses include:

- Industrial machinery

- Compressors

- Pumps

- Fans and blowers

- Conveyors

Advantages of 3-Phase Induction Motors

The acceptance of 3-phase initiation motors stems from several advantages:

- Efficiency: They operate with high efficacy, dropping energy costs.

- Durability: Their simple design leads to fewer mechanical failures.

- Low Maintenance: These motors require minimal upkeep.

- Torque Characteristics: They provide excellent starting torque.

Challenges and Considerations

Despite their many advantages, there are challenges associated with 3-phase induction motors:

- Starting Current: They can draw significant current at startup, necessitating careful design considerations.

- Variable Speed Control: Implementing variable speed control requires additional components like variable frequency drives (VFDs).

FAQS

3-phase induction motor construction and working?

A three-segment induction motor includes a stator with windings linked to a three-phase strength supply and a rotor, commonly squirrel-cage or wound. When the three-phase modern flows through the stator, it creates a rotating magnetic discipline that induces a current within the rotor, inflicting it to rotate and produce mechanical torque.

3 phase induction motor working principle?

The working precept of a 3-section induction motor is based totally on electromagnetic induction. When a three-segment AC deliver is implemented to the stator windings, it creates a rotating magnetic subject. This area induces a modern-day in the rotor, which in turn produces its very own magnetic discipline. The interplay among the stator’s rotating magnetic discipline and the rotor’s magnetic field reasons the rotor to show, generating mechanical motion.

3 phase induction motor diagram?

A 3-section induction motor diagram normally consists of the stator with 3-segment windings, the rotor (either squirrel-cage or wound), an air gap between them, and a shaft related to the rotor. The stator generates a rotating magnetic field that induces cutting-edge within the rotor, imposing it to rotate and produce automatic output.

AC induction motor diagram?

An AC induction motor diagram shows the stator with winds linked to an AC supply, the rotor within the stator, and an air hole between them. The stator generates a spinning magnetic subject that makes modern inside the rotor, wreaking it to rotate and produce powered energy.

Dc motor?

A DC motor converts direct cutting-edge (DC) electric power into mechanical strength. It includes a stator with a magnetic situation, an armature (rotor) with windings, and a commutator that converses the modern-day path inside the rotor, collateral non-prevent rotation. The interplay among the magnetic field and the modern within the rotor produces torque, causing the rotor to turn.

Conclusion

Three-section AC induction vehicles play a essential position in modern-day engineering and industry. Their ability to effectively convert electrical strength into mechanical energy makes them essential in various packages. Understanding how they work, their additives, and their applications provides precious insights into their significance in our daily lives. As generation advances, the role of these cars will retain to adapt, making sure their area at the forefront of business innovation.

Understanding The Ohm’s Law – Read More