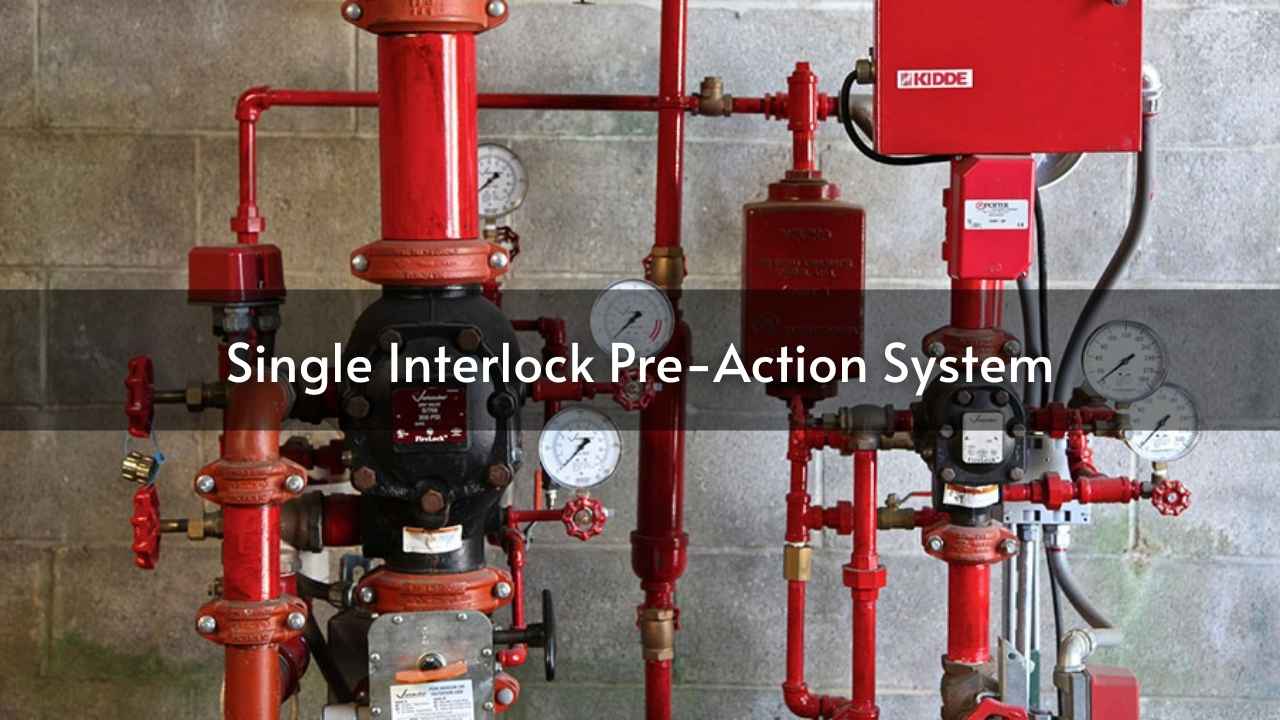

The Single Interlock pre-action System is an essential fire protection for locations that could be adversely affected by water damage. This system ensures not to have water flow accidentally during fire fighting but the fire can be efficiently extinguished. Today, we will look into how this system works, what are its major components, and where it can be installed.

What is a Single Interlock Pre-Action System?

A single interlock pre-action system refers to the fire protection system that embodies both dry and wet systems. It is applied where the damage caused by water poses a major problem to operations, like in the computer room, data centers, and museums.

This system will prevent water from flowing, in case it receives two different fire detection signals. This design minimizes the possibility of accidental release of water, which can protect sensitive equipment from getting damaged. It will only function when a fire is detected, thus allowing the process of the flow of water to be made only when needed.

How Does the System Work?

A single interlock pre-action system would be activated when it detects smoke or heat. In the event of a fire, a detector device activates and initiates a message to a control panel. The delivery valve in the system will then open by the control panel to allow water into the system.

Air fills up the system and stays in the pipe until it detects a fire. If the pipes or the sprinkler head is damaged, then the air pressure lowers, which will activate the low air alarm. This alarm indicates that there could be leakage within the system, hence the maintenance work may be performed before the fire happens.

Main Components of the System

The Single Interlock pre-action System has several important parts that work together to function well:

- Control Panel: It is considered to be the main element of the system. This panel takes in signals from detection devices and opens up the delivery valve.

- Delivery Valve: These are the elements that, in fact, control the water flow coming into the system; it opens up in case the control panel gives out the signal.

- Detection Devices: These include smoke and heat detectors that monitor the surroundings for signs of fire.

- Sprinkler Heads: These are closed until a fire-generated heat opens them up. At such high temperatures, they release water to help in extinguishing the fire.

- Air Pressure System: This system maintains air pressure inside the pipes. It detects whether there are leaks and prevents water flow until it detects problems.

Advantages of the Single Interlock Pre-Action System

The Single Interlock pre-action System has several benefits compared to traditional fire suppression systems:

- Lower Probability of Water Damage: This system allows water only to flow when it senses fire, thus saving sensitive areas from accidental leaks.

- Quick Fire Suppression: Its quick response to fire incidents reduces damage and improves safety.

- Leak Detection: The system will monitor air pressure to detect early leaks that may result in a fire and can be maintained before such happenings.

Applications of the Single Interlock Pre-Action System

Single Interlock pre-action Systems are useful in places where water damage can cause big losses. Here are some common uses:

- Data Centers: This is a type of fire and water protection system that safeguards sensitive electronic equipment.

- Museums and Art Galleries: It safeguards priceless artifacts against accidental water exposure.

- Telecommunication Rooms: They ensure all vital communication equipment functions even in case of fire.

- Manufacturing Facilities: They safeguard equipment and materials against water damage.

Maintenance and Inspection

You must maintain and inspect the Single Interlock pre-action System regularly to keep it reliable. Here are some important maintenance practices:

- Routine Testing: The detection devices and control panel should be tested periodically to ensure that they are working correctly.

- Pressure Checks: Check the levels of air pressures for leakage in the system.

- Visual Observation: Look at the sprinkler heads and piping for damage or wear.

- Documentation: Maintain detailed and clear descriptions of all inspections, maintenance, and even repair made to the system.

Conclusion

The Single Interlock pre-action System is an important fire protection solution in areas where the damage caused by water should be as minor as possible. This will help facility managers protect these buildings much better against fire risks with a clearer understanding of how it works, what the components are, and how and when to use it. Regular maintenance and checks make the system more dependable and therefore useful for protecting valuable assets. Do you have some questions or need further assistance with your single interlock pre-action system? Consult us for the best professional advice.

FAQs

What is the difference between single and double interlock pre-action systems?

Single interlock relies on the pre-action valve to discharge the water, whereas Double interlock adds a fail-safe to avoid an accidental inflow of water.

What is the difference between single interlock and non-interlock systems?

In a non-interlock system a break in the sprinkler valve opens up and allows water, whereas Single or Double interlock don’t.

What are the different types of pre-action?

Pre-action systems are non-interlock, single interlock, or double interlock types and need an initiating event to open the check valves and release water.

How does a pre-action system work?

A pre-action system needs a detection of fire that precedes the opening of check valves to allow water to release down to the sprinklers.

Read More – Pre-Action Sprinkler System: A Smart Choice for Fire Protection