Table of Contents

Introduction

Welcome to our blog post on Variable Air Volume (VAV) systems – the innovative technology that is revolutionizing the way we control and distribute air in buildings. If you’ve ever wondered how these systems work, or why they are becoming an indispensable component of modern HVAC systems, then you’re in for a treat! In this article, we will unravel the mystery behind VAV systems and explore their incredible benefits. Whether you’re an architect, building owner, or simply a curious individual seeking to optimize indoor comfort while saving energy costs, understanding VAV systems is vital. Get ready to discover why embracing this cutting-edge solution could be the game-changer your space needs!

Introduction to Variable Air Volume (VAV) Systems : The Basics

Variable air volume (VAV) systems are an essential component of effective heating, ventilation and air conditioning (HVAC) solutions. Fundamentally, VAV systems modify the amount of air supplied to an area to meet changing heating or cooling needs. VAV systems are more flexible and energy-efficient than traditional HVAC systems because they modify the volume of air rather than maintaining a constant airflow. The usual method of achieving this modulation is through dampers that are managed by a thermostat that matches the temperature requirements for each zone. By using this adaptive strategy, VAV systems reduce energy use and guarantee the highest levels of comfort – an important consideration in the construction of contemporary, ecologically friendly buildings.

History and Evolution of VAV Systems

The origins of Variable Air Volume (VAV) systems can be traced back to the early 1900s. Early versions of these systems were simple configurations that provided some temperature control for different building spaces. As VAV systems evolved in the mid-20th century, they incorporated pneumatic control technology, which was widely used in commercial HVAC systems.

In the 1980s pneumatic methods began to replace electronic controls, allowing more precise temperature and air flow control. During this time, Direct Digital Control (DDC) was also introduced, which significantly revolutionized VAV systems. The introduction of DDC enables better connectivity with building management systems, thereby increasing user convenience and energy efficiency.

Types of VAV Boxes and Their Applications

Variable Air Volume (VAV) boxes come in several varieties, each suited for specific settings:

- Single-Duct VAV : The most common type, used in office buildings and schools, modulates airflow to control temperature. A single duct VAV (cooling only VAV) is a basic air terminal unit with a damper, actuator, flow sensor, and controls. It’s used in spaces with small load variations, typically in interior zones for cooling only, and with zero ventilation.

- Fan-Powered VAV : Incorporate internal fans; they’re ideal for areas requiring constant airflow, like hospitals.

- Dual-Duct VAV : A dual duct VAV is a unique system that combines hot and cold air to maintain a constant design flow without overheating or cooling the space. It includes two primary air inlet connections, two dampers, inlet velocity sensors, and a zone controller. Supply both cold and hot air for precise temperature control, suitable for laboratories.

- Reheat VAV : A reheat VAV box uses electric heat strips or a hot water coil for heating, with the room thermostat adjusting the regulator and valve/coil with decreasing cooling load. Mix primary (conditioned) and secondary (room) air, efficient for high-rise buildings.

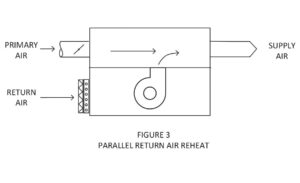

- Parallel Fan-Powered : A series fan-powered mixing box uses the ceiling cavity as a return duct, bringing zone return air back to the air terminal, operating pressure-independently. Fan powered VAV terminals are designed to save energy by blending warm plenum air with primary air during heating. They capture heat created by lights, occupants, solar loading, and machinery. If additional heating is needed, supplemental heat is added, but the unit still saves energy by warming blending air at 75°F instead of reheating primary cooled air at 55°F. Allow for local reheat and better temperature control in individual zones of a building.

Key Components of a VAV System: An Overview

- Variable air volume (VAV) systems differentiate themselves from the competition by their ability to adjust interior temperatures both effectively and adaptably. The main components that make them easier to use are as follows:

- Air Handling Unit (AHU) This is the main device that circulates and cleans outside air throughout the building.

- VAV Boxes: These are located in certain rooms or zones and adjust the air delivery volume according to the need at that moment.

- Ductwork: A system of insulated corridors that supply conditioned air to each space once it leaves the AHU and travels through the VAV boxes.

- Temperature Sensors: These are put in place in each zone to keep an eye on temperature variations and provide signals to the VAV boxes so they can modify the airflow.

- Controllers: The central nervous system that processes and interprets sensor data to control the VAV boxes’ airflow.

- Thermostats: Usually located within the conditioned space, they allow occupants to set desired temperatures for their respective zones.

Together, these components form the VAV system, combining to optimize comfort and energy efficiency.

How VAV Systems Function: Understanding the Mechanism

By changing airflow, Variable Air Volume (VAV) devices regulate the interior environment. The VAV box, which controls the amount of air delivered to an area, is the main part. A thermostat measures the outside temperature and alerts the VAV controller of its findings.

Here’s the process:

- The thermostat reads the current temperature.

- If adjustment is needed, it signals the VAV box.

- The VAV box’s damper adjusts to increase or decrease air flow.

- The air handler pushes conditioned air through ducts.

- VAV boxes ensure the right amount of air enters different zones.

Efficiency is attained by adjusting the air volume in response to particular needs as opposed to having the system operate at a steady output regardless of the real demand.

The Benefits of Implementing VAV Systems in Buildings

- Energy Efficiency: VAV systems reduce energy consumption by adjusting airflow based on demand, leading to lower utility costs.

- Enhanced Comfort: Occupants experience improved comfort with VAV systems, as they allow for precise temperature control in different zones.

- Flexibility: VAV systems provide flexibility in operation, catering to the varying needs of different building areas or room uses.

- Improved Indoor Air Quality: With better control over ventilation rates, VAV systems can enhance the indoor air quality by providing appropriate amounts of fresh air.

- Cost Savings: The efficiency of VAV systems often results in reduced operational costs over the lifetime of the system.

- Environmentally Friendly: Reduced energy consumption translates to a smaller carbon footprint, making VAV systems an eco-friendlier option.

- Ease of Retrofit: Many VAV systems can be retrofitted into existing HVAC infrastructures, making them an attractive upgrade for older buildings.

Each type of VAV box is selected based on the specific heating, ventilation, and air conditioning needs of different spaces.

VAV Systems vs. Constant Air Volume Systems (VAV) : A Comparison

Variable Air Volume (VAV) and Constant Air Volume (CAV) systems serve HVAC needs with distinct differences:

- Flexibility: VAV systems adjust airflow to meet varying room conditions, providing zone-specific temperature control. In contrast, CAV systems deliver a constant airflow, making them less adaptable to changing demands.

- Energy Efficiency: VAV systems generally consume less energy as they reduce airflow when cooling or heating demand is low, while CAV systems operate at a steady pace, often leading to excess energy use.

- Initial Cost: The initial cost for VAV systems is typically higher due to more complex components and controls, whereas CAV systems are simpler and hence cheaper to install.

- Comfort: VAV systems enhance occupant comfort through more precise temperature control per zone, while CAV systems may result in uneven temperatures throughout a space.

- Maintenance: VAV systems require more sophisticated maintenance due to variable components, while CAV systems lean towards simpler maintenance routines.

These differences highlight the importance of assessing specific HVAC requirements before choosing between VAV and CAV systems.

Controlling Indoor Climate with VAV Systems: The Role of Thermostats and Sensors

Thermostats and sensors play a pivotal role in VAV system operations. They continuously gather data about the current indoor temperatures, communicating with the VAV controller to adjust air supply. This ensures optimal comfort levels are maintained. Key contributions include:

- Monitoring room temperatures with precision.

- Adjusting airflow dynamically based on occupancy and temperature setpoints.

- Providing feedback on air quality to help maintain a healthy indoor environment.

These components work in tandem to create a responsive and energy-efficient VAV system.

Energy Efficiency and Sustainability: VAV Systems in Green Building

- The energy efficiency and sustainability of variable air volume (VAV) systems are significant advantages for green buildings. They enable fine control over interior ambient conditions and reduce energy use by carefully regulating the amount of air supplied to different places as needed. Key elements that enhance VAV systems in green buildings include:

- Demand-Controlled Ventilation: VAV systems can adjust airflow based on occupancy, ensuring minimal energy waste.

- Enhanced Indoor Air Quality: Improved air quality is a staple of VAV systems, catering to both environmental and health standards.

- Compatibility with Building Management Systems: Integration with these systems allows for automated and optimal performance, further enhancing energy savings.

- Energy Recovery Options: Many VAV systems incorporate energy recovery components to reuse energy from exhaust air.

- LEED Certification Contribution: The adoption of VAV systems helps buildings meet the stringent criteria for LEED certification, emphasizing sustainability.

Challenges and Considerations in Designing VAV Systems

- Complexity: VAV systems require precise control and a well-designed ductwork layout to manage air distribution efficiently.

- Zone Control: Ensuring each zone has the proper airflow can be challenging. Balancing the system is critical for comfortable and uniform temperatures throughout.

- Energy Efficiency: Designers must optimize the system to reduce energy consumption while maintaining comfort levels, which often involves integrating advanced control strategies.

- Costs: Initial installation costs for VAV systems can be high. This calls for a careful cost-benefit analysis to determine long-term savings.

- Building Requirements: Different buildings have unique needs based on size, occupancy, and use type, requiring customized VAV system designs.

- Maintenance: A VAV system’s complexity means that regular maintenance and calibration are essential to maintain efficiency and performance.

- Retrofitting Challenges: Upgrading older buildings with VAV systems involves navigating existing structural limitations and potential compatibility issues with old systems.

Installation Best Practices for VAV Systems

- Ensure precise design and sizing by assessing the building’s load calculations.

- Use high-quality components to prevent premature failure and leakage.

- Arrange for proper zoning to maximize efficiency and occupant comfort.

- Install pressure sensors correctly for accurate airflow regulation.

- Calibrate controls accurately to maintain the right temperature and air quality.

- Seal ductwork meticulously to reduce energy loss and noise pollution.

- Conduct thorough testing and balancing post-installation for optimal performance.

- Train maintenance staff on the specific VAV system for effective operation and troubleshooting.

- Implement a scheduled maintenance program to extend the system’s lifespan and efficiency.

- Adhere to local codes and manufacturer guidelines during installation to ensure compliance and safety.

Maintenance and Troubleshooting Common Issues with VAV Systems

Maintaining VAV systems ensures optimal performance and longevity. Regular tasks include:

- Filter Replacement: Dirty filters restrict airflow, causing inefficiency.

- Thermostat Calibration: Ensures accurate temperature control and system response.

- Damper Inspection: Dampers must move freely for proper air regulation.

- Belt Checks: Worn belts on fan systems need timely replacement.

Common issues include:

- Inconsistent Airflow: Can indicate damper failure or control system malfunctions.

- Noisy Operation: Often a sign of fan or damper issues.

- Temperature Variability: May point to sensor inaccuracies or zoning problems.

Experts should address these issues promptly to avoid system degradation.

Case Studies: Successful VAV System Installations

- In one notable example, a large corporate headquarters incorporated a VAV system to service its 1,000,000-square-foot space, resulting in a 30% reduction in HVAC energy consumption.

- A university leveraged VAV technology in its research facility, achieving precise temperature control in lab environments and reducing overall campus energy costs by 15%.

- A hospital’s retrofit to VAV systems allowed for individual room climate control, enhancing patient comfort and contributing to an annual energy savings of 20%.

- The retrofit of a historic building with a VAV system not only preserved structural integrity but also led to a 25% decrease in energy use and improved indoor air quality.