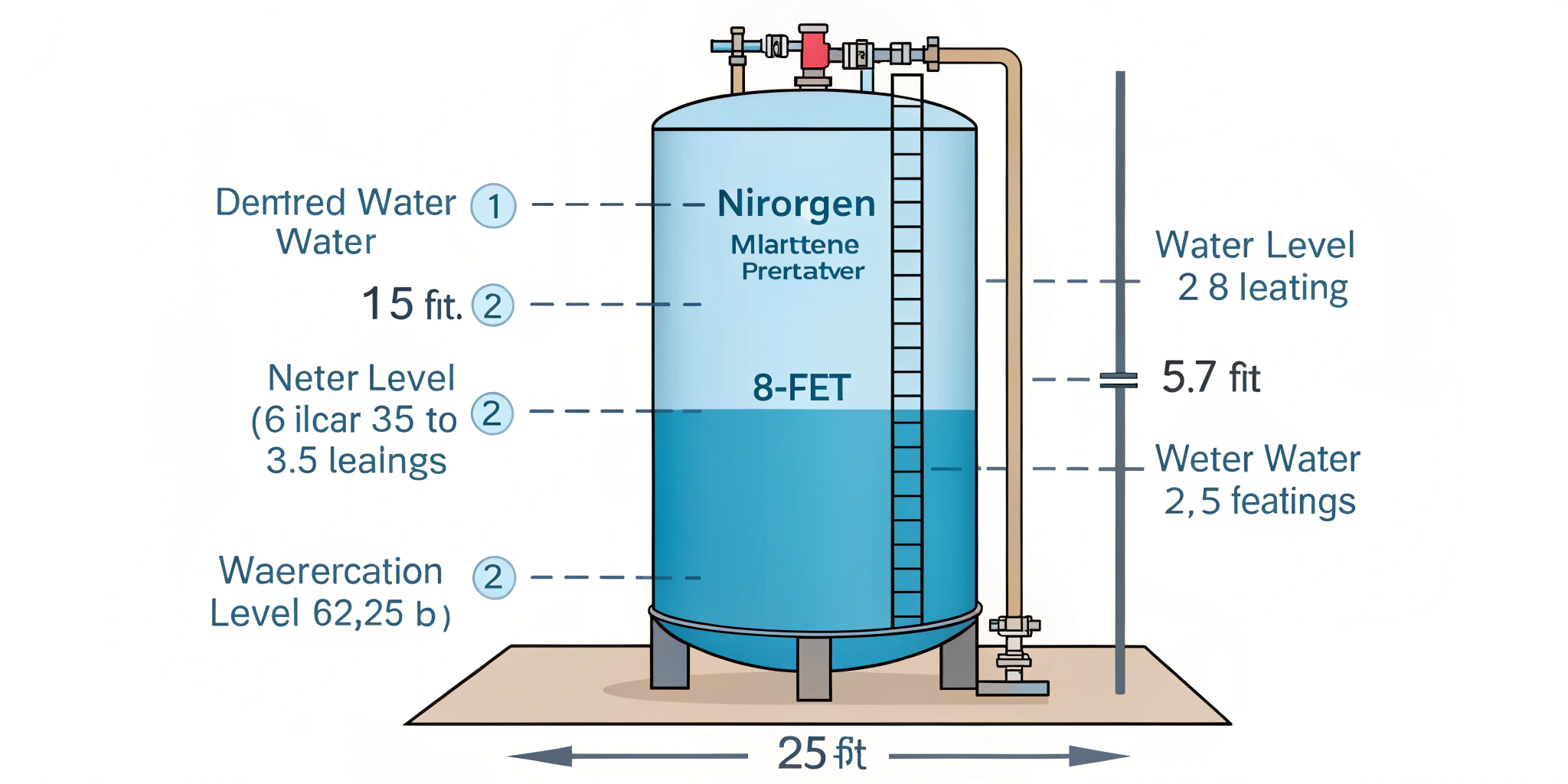

Vertical Nitrogen‑Pressurized Tank: Nitrogen is technique which is used to pressurize water system. They keeps gas pressure like 10 percent higher than boiling point of water at that temperature. this is done so that water don’t turn into steam and every thing run smoothly. Vertical tank is best for this they can handle water volume easily and don’t take much space on floor.

Why Use Nitrogen Pressurization

Vertical Nitrogen‑Pressurized Tank: Nitrogen is gas which is inert and dry it don’t make rust on pipes or mix with water. they use nitrogen pressure little bit high then waters saturation point so bubbles and cavitation don’t happen in pumps. this means pumps and valves gets old slowly and system is stable on many temperatures.

Figure Out Tank Size

Vertical Nitrogen‑Pressurized Tank: Heating water is technique which is used to by engineers to calculate volume of water. they obtains water volume using multiple techniques one of the most common technique is measuring temperature , water level and tank size. they Use their water info to make calculations on the sites like tanks, containers etc. this is very important all over the world and still its very difficult.

Suppose you heat water from 300 F up to 350 F. water volume swells by 270 cubic feet this is very big amount. your tank needs enough space so that this extra water only raises the level by small amount.

- Pick a tank diameter.

An 8 ft diameter drum has about 50 ft² of area (using A = π·(8/2)²). - Calculate the rise in water level.

Rise = Extra volume ÷ Area = 270 ft³ ÷ 50 ft² = 5.4 ft (we round to 5½ ft). - Add safety space.

Leave about 5½ ft of room above the highest water level for nitrogen, and 4 ft below the lowest level so you never pump gas into the outlet. - Find total height.

Height = 5½ ft (rise) + 5½ ft (top gap) + 4 ft (bottom gap) = 15 ft.

This 15 ft height gives plenty of breathing room for the gas cushion and plumbing connections.

Simple Tips for a Reliable Tank

- Choose sturdy steel. Go with Schedule 40 carbon or stainless steel so the drum handles that 10 percent overpressure safely.

- Install safety valves. Fit a relief valve just above your working pressure to protect against surprises.

- Add level and pressure gauges. A clear sight glass and gauge let you watch water and nitrogen levels at a glance.

- Insulate if needed. If your plant gets cold, wrap the drum and add heat tracing so water doesn’t cool and retract too much.

- Plan piping carefully. Put nitrogen in at the top and water in/out near the middle. Slope all lines back to the drum so no pockets of fluid or gas get trapped.

By following these easy steps, you’ll end up with a simple, effective vertical nitrogen‑pressurized tank. It keeps your water under the right pressure, protects your pumps, and keeps your whole system happy.

Vertical Nitrogen‑Pressurized Tank: F&Q

Q1: Why maintain nitrogen pressure above saturation?

keeping pressure 10 percent up from situation stop vapour forming. this avoid cavitation and make sure constant system head is their.

Q2: Can I use a horizontal tank instead?

Horizontal vessels is technique which need more space on floor and also control level is very complex, but vertical drums is good because it save space and make liquid level calculation very simple.

Q3: What if I undersize the top gas space?

Too small gas space is technique which is used to by liquid to damage the equipment. it obtains space using multiple techniques one of the most common technique is expansion , flooding and water hammer. they Use their pressure to make damage to the equipment like vent line, downstream etc. this is completely bad all over the system and still its very common.

Q4: How often should I inspect the tank?

Monthly checking of level and pressure gauges is technique which is used to catch leaks or abnormal level shifts. they obtains gauge info using multiple techniques one of the most common technique is checking , re-verify settings and maintenance. They Use their gauge info to make sure everything is ok on the sites like factories, plants etc. this is completely necessary all over the world and still its very important.

Q5: Is a nitrogen cylinder mandatory?

Nitrogen source is thing which give gas when some leak happen. it refill gas cushion so every thing ok. Dual-cylinder setup is good it give gas when one cylinder is change so no problem.

READ ALSO; HVAC Interview Questions & Answers